Subjects of metrology: their rights, responsibilities and functions. Subjects of metrology

Metrology authorities. State policy and legal regulation in the field of ensuring the uniformity of measurements is carried out by the federal body for technical regulation - the Ministry of Industry and Energy of Russia. The specified federal body adopts the following regulatory legal acts in the field of metrology:

Rules for the creation, approval, storage and application of standards of units of quantities;

Metrological rules and regulations;

The procedure for the development and certification of measurement techniques;

The procedure for submitting measuring instruments for verification and testing, as well as establishing intervals between verifications;

The procedure for accreditation for the right to perform calibration work and issuance of a calibration certificate;

The procedure for carrying out state metrological control.

Agency for technical regulation and metrology operating within the Ministry of Industry and Energy of Russia - FA ≪ Rostekhregulirovanie" carries out:

Management of the activities of the State Metrological Service and state reference metrological services;

Determination of general metrological requirements for means, methods and results of measurements;

Maintaining a state register of approved types of measuring instruments;

State metrological supervision.

The function of state metrological supervision is performed by the FA “Rostekhregulirovanie” directly and through seven interregional territorial departments. The functions of state metrological control continue to be performed “on the spot” by federal government institutions - centers of standardization, metrology and certification (FGU TsSM). There are more than 90 FMCs operating in Russia.

Metrology services. Ensuring the uniformity of measurements in the country is carried out by the following metrology entities:

State Metrological Service (SMS);

Reference metrological services (CMS);

Metrological services of federal executive authorities;

Metrological services of organizations (MSO).

The GMS includes:

Divisions of the central office of the FA “Rostekhregulirovanie”, carrying out the functions of planning, management and control of activities to ensure the uniformity of measurements (UME) at the intersectoral level;

State scientific metrological centers;

State Migration Service bodies in the constituent entities of the Russian Federation (in the territories of republics within the Russian Federation, autonomous region, autonomous districts, territories, regions, districts and cities) - CSM.

State scientific metrological centers are represented by the following institutes:

All-Russia Research Institute of Metrological Service (VNIIMS, Moscow);

All-Russian Research Institute of Metrology named after. DI. Mendeleev (VNIIM, St. Petersburg);

NPO “VNII of physical, technical and radio engineering measurements” (VNIIFTRI, Mendeleevo village, Moscow region);

Ural Research Institute of Metrology (UNIIM, Yekaterinburg), etc.

These scientific centers are not only engaged in the development of scientific and methodological foundations for improving the Russian measurement system, but are also holders of state standards.

In Russia there are more than 90 CMS (respectively their metrological divisions), which perform the functions of regional HMS bodies in the territories of the constituent entities of the Russian Federation, the cities of Moscow and St. Petersburg.

FA ≪Rostekhregulirovanie≫ carries out methodological management of three state help services:

State Service for Time, Frequency and Determination of Earth Rotation Parameters (GSHF);

State Service for Standard Samples of the Composition and Properties of Substances and Materials (GSSO);

State Service for Standard Reference Data on Physical Constants and Properties of Substances and Materials (GSSSD).

Metrological services Federal executive authorities and legal entities can be created in ministries (departments), organizations, enterprises and institutions that are legal entities to carry out work to ensure the uniformity and required accuracy of measurements, and carry out metrological control and supervision.

If at fairly large enterprises (in legally approved areas) full-fledged MSs are organized, then at small enterprises it is recommended to appoint persons responsible for ensuring the uniformity of measurements. A job description is approved for responsible persons, which establishes their functions, rights, duties and responsibilities.

The main tasks of metrological services:

Calibration of measuring instruments;

Supervision of the condition and use of measuring instruments, certified methods of performing measurements, standards of units of quantities used for calibration of measuring instruments, compliance with metrological rules and regulations, regulatory documents to ensure the uniformity of measurements;

Issuance of mandatory instructions aimed at preventing, stopping or eliminating violations of metrological rules and regulations;

Verifying the timeliness of submission of measuring instruments for testing in order to approve the type of measuring instruments, as well as for verification and calibration;

Analysis of the state of measurements, testing and control at the enterprise, in the organization.

Metrological services of enterprises must pay special attention to the state of measurements, compliance with metrological rules and norms in the areas of enterprise activity provided for by the Federal Law “On Ensuring the Uniformity of Measurements” (Article 13): when testing and monitoring product quality in order to determine compliance with the mandatory requirements of state standards, when performance by the enterprise of work on mandatory certification of products and services, etc.

In its activities, the State Migration Service of Russia takes into account documents from international regional metrology organizations.

Three main functions of measurement in the national economy can be distinguished:

accounting of national economic products, calculated by weight, length, volume, consumption, power, energy;

measurements carried out to control and regulate technological processes (especially in automated production) and to ensure the normal functioning of transport and communications;

measurements of physical quantities, technical parameters, composition and properties of substances carried out during scientific research, testing and control of products in various sectors of the national economy.

The efficiency of performing these functions depends on the quality of measuring instruments.

Increasing the accuracy of measurements makes it possible to identify the shortcomings of certain technological processes and eliminate these shortcomings. All this ultimately leads to improved product quality, saving energy and heat resources, as well as raw materials.

3. Metrology: basic concepts, structural elements, goals, objectives, principles, interdisciplinary connections.

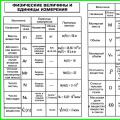

1) a physical quantity, which is a general property in relation to the quality of a large number of physical objects, but individual for each in the sense of quantitative expression;

2) a unit of a physical quantity, which means a physical quantity to which, by condition, a numerical value equal to one is assigned;

3) measurement of physical quantities, which means quantitative and qualitative assessment of a physical object using measuring instruments;

4) a measuring instrument, which is a technical device that has standardized metrological characteristics. These include a measuring device, a measure, a measuring system, a measuring transducer, a set of measuring systems;

5) a measuring device is a measuring instrument that produces an information signal in a form that would be understandable for direct perception by an observer;

6) measure – also a means of measurement that reproduces a physical quantity of a given size. For example, if a device is certified as a measuring instrument, its scale with digitized marks is a measure;

7) a measuring system, perceived as a set of measuring instruments that are connected to each other through information transmission channels to perform one or more functions;

8) measuring transducer – also a measuring instrument that produces an information measuring signal in a form convenient for storage, viewing and broadcasting via communication channels, but not accessible for direct perception;

9) the principle of measurements as a set of physical phenomena on which measurements are based;

10) measurement method as a set of techniques and principles for using technical measuring instruments;

11) measurement methodology as a set of methods and rules developed by metrological research organizations, approved by law;

12) measurement error, which is a slight difference between the true values of a physical quantity and the values obtained as a result of measurement;

13) the basic unit of measurement, understood as a unit of measurement that has a standard that is officially approved;

14) a derivative unit as a unit of measurement related to the basic units based on mathematical models through energy relationships, which does not have a standard;

15) a standard, which is intended for storing and reproducing a unit of physical quantity, for transmitting its dimensional parameters to measuring instruments that are lower in the verification scheme. There is the concept of “primary standard”, which means a measuring instrument that has the highest accuracy in the country. There is the concept of “comparison standard”, interpreted as a means for connecting standards of interstate services. And there is the concept of “standard copy” as a means of measurement for transferring the sizes of units to standard means;

16) exemplary means, which is understood as a measuring instrument intended only for transmitting the dimensions of units to working measuring instruments;

17) a working instrument, understood as “a measuring instrument for assessing a physical phenomenon”;

18) measurement accuracy, interpreted as the numerical value of a physical quantity, the inverse of the error, determines the classification of standard measuring instruments. According to the accuracy of measurements, measuring instruments can be divided into: highest, high, medium, low.

Main tasks of metrology.

The tasks of metrology include:

1) development of a general measurement theory;

2) development of measurement methods, as well as methods for establishing the accuracy and precision of measurements;

3) ensuring the integrity of measurements;

4) determination of units of physical quantities.

4. Objects of metrology: concept, characteristics of quantities: size, dimension. Values of measured quantities.

The following main measurement characteristics are distinguished:

1) the method by which measurements are taken;

2) measurement principle;

3) measurement error;

4) measurement accuracy;

5) correctness of measurements;

6) reliability of measurements.

Measurement method- this is a method or a set of methods by which a given quantity is measured, i.e., a comparison of the measured quantity with its measure according to the accepted principle of measurement.

There are several criteria for classifying measurement methods.

1. According to the methods of obtaining the desired value of the measured quantity, the following are distinguished:

1) direct method (carried out using direct, direct measurements);

2) indirect method.

2. According to measurement techniques, there are:

1) contact measurement method;

2) non-contact measurement method. The contact measurement method is based on direct contact of any part of the measuring device with the measured object.

With the non-contact measurement method, the measuring device does not come into direct contact with the object being measured.

3. According to the methods of comparing a quantity with its measure, the following are distinguished:

1) direct assessment method;

2) method of comparison with its unit.

The direct assessment method is based on the use of a measuring device that shows the value of the measured quantity.

The method of comparison with a measure is based on comparing the measurement object with its measure.

Measuring principle– this is a certain physical phenomenon or their complex on which the measurement is based. For example, temperature measurement is based on the phenomenon of expansion of a liquid when it is heated (mercury in a thermometer).

Measurement error is the difference between the result of measuring a quantity and the real (actual) value of this quantity. Error, as a rule, arises due to insufficient accuracy of measurement tools and methods or due to the inability to provide identical conditions for repeated observations.

Accuracy of measurements– this is a characteristic that expresses the degree of correspondence of the measurement results to the real value of the measured quantity.

Quantitatively, the measurement accuracy is equal to the relative error minus the first power, taken modulo.

Correct measurement– this is a qualitative characteristic of a measurement, which is determined by how close to zero the value of a constant or fixed error that changes during repeated measurements (systematic error). This characteristic usually depends on the accuracy of the measuring instruments.

The main characteristic of measurements is the reliability of the measurements.

Reliability of measurements is a characteristic that determines the degree of confidence in the obtained measurement results. According to this characteristic, measurements are divided into reliable and unreliable. The reliability of measurements depends on whether the probability of deviation of the measurement results from the real value of the measured value is known. If the reliability of the measurements is not determined, then the results of such measurements, as a rule, are not used. The reliability of measurements is limited above by the measurement error.

5. Units of physical quantities: concept, classification. International system of physical quantities / SI / application in Russia.

physical quantity(quantity) is a property that is qualitatively common to many physical objects (physical systems, their states and processes occurring in them), but quantitatively individual for each object.”

Measuring instrument (MI)– this is a technical means or a set of means used to carry out measurements and having standardized metrological characteristics. With the help of measuring instruments, a physical quantity can not only be detected, but also measured.

Basic units: kilogram, meter, second, ampere, kelvin, mole and candela. Within the SI framework, these units are considered to have independent dimensions, that is, none of the basic units can be obtained from the others.

Derived units are obtained from basic units using algebraic operations such as multiplication and division. Some of the derived units in the SI are given their own names.

Prefixes can be used before unit names; they mean that a unit must be multiplied or divided by a certain integer, a power of 10. For example, the prefix “kilo” means multiplied by 1000 (kilometer = 1000 meters). SI prefixes are also called decimal prefixes.

The SI system is a development of the metric system of measures, which was created by French scientists and first widely introduced after the French Revolution. Before the introduction of the metric system, units were chosen randomly and independently of each other. Therefore, conversion from one unit to another was difficult. In addition, different units were used in different places, sometimes with the same names. The metric system was supposed to become a convenient and uniform system of measures and weights.

In 1799, two standards were approved - for a unit of length (meter) and for a unit of mass (kilogram).

In 1874, the GHS system was introduced, based on three units - centimeter, gram and second. Decimal prefixes from micro to mega were also introduced.

In 1889, the 1st General Conference on Weights and Measures adopted a system of measures similar to the GHS, but based on the meter, kilogram and second, since these units were considered more convenient for practical use.

Subsequently, basic units were introduced for physical quantities in the field of electricity and optics.

In 1960, the XI General Conference on Weights and Measures adopted a standard that was first called the International System of Units (SI).

In 1971, the XIV General Conference on Weights and Measures amended the SI, adding, in particular, a unit of quantity of a substance (mole).

The SI is now accepted as a legal system of units by most countries in the world and is almost always used in the scientific field (even in those countries that have not adopted the SI).

6. Subjects of metrology: bodies and services, functions.

Metrological service- this is a set of subjects of activity and types of work aimed at ensuring the uniformity of measurements. Currently, the metrological service of Russia consists of the State Metrological Service, which is managed by Rostechregulirovanie, as well as metrological services of government bodies and legal entities.

State Metrological Service carries out work to ensure the uniformity of measurements in the country at the interregional and intersectoral level and carries out state metrological control and supervision.

The main tasks of metrological services include:

· verification and calibration of measuring instruments;

· supervision over the condition and use of measuring instruments, over certified measurement techniques and standards of units of quantities used for calibration of measuring instruments, over compliance with metrological rules and regulations and regulatory documents to ensure the uniformity of measurements;

· issuance of mandatory instructions aimed at preventing, stopping or eliminating violations of metrological rules and regulations;

· checking the timeliness of submission of measuring instruments for testing for type approval, as well as for verification and calibration;

· analysis of the state of measurements, testing and control at the enterprise.

The general management of the HMS is carried out by the State Standard of the Russian Federation, which is assigned the following functions by the Law “On Ensuring the Uniformity of Measurements”:

1. interregional and intersectoral coordination of activities to ensure uniformity of measurements;

2. submission to the Government of the Russian Federation of proposals for units of quantities allowed for use;

3. establishing rules for the creation, approval, storage and use of standards of units of quantities;

4. determination of general metrological requirements for means, methods and results of measurements;

5. state metrological control and supervision;

6. control over compliance with the terms of international treaties of the Russian Federation on the recognition of test results and verification of measuring instruments;

7. management of the activities of the State Metrological Service and other state services to ensure the uniformity of measurements;

8. participation in the activities of international organizations on issues of ensuring the uniformity of measurements;

9. approval of regulatory documents to ensure the uniformity of measurements;

10. approval of state standards;

11. establishment of verification intervals for measuring instruments;

12. classification of technical devices as measuring instruments;

13. establishing a procedure for the development and certification of measurement techniques;

14. maintaining and coordinating the activities of the State Scientific Metrological Centers (SSMC), the State Metrological Service, the State Service of Time and Frequency (GSVCh), the State Service of Standard Samples (GSSO), the State Service of Standard Reference Data (GSSSD);

15. accreditation of state testing centers for measuring instruments;

16. approval of the type of measuring instruments;

17. maintaining the State Register of Measuring Instruments;

18. accreditation of metrological services of legal entities for the right to verify measuring instruments;

19. approval of lists of measuring instruments subject to verification;

20. establishing a procedure for licensing the activities of legal entities and individuals in the manufacture, repair, sale and rental of measuring instruments;

21. organization and coordination of the activities of state inspectors to ensure the uniformity of measurements;

22. organization of activities and accreditation of metrological services of legal entities for the right to carry out calibration work;

23. planning and organization of metrological work.

7. Measurements: concept, classification of measurements.

Measurement - a set of operations to determine the ratio of one (measured) quantity to another homogeneous quantity, taken as a unit stored in a technical device (measuring instrument). The resulting value is called the numerical value of the measured quantity; the numerical value together with the designation of the unit used is called the value of the physical quantity. The measurement of a physical quantity is carried out experimentally using various measuring instruments - measures, measuring instruments, measuring transducers, systems, installations, etc. The measurement of a physical quantity includes several stages: 1) comparison of the measured quantity with a unit; 2) transformation into a form convenient for use (various display methods).

Direct measurement- measurement in which the desired value of a physical quantity is obtained directly.

Indirect measurement- determination of the desired value of a physical quantity based on the results of direct measurements of other physical quantities that are functionally related to the desired quantity.

Joint measurements- simultaneous measurements of two or more different quantities to determine the relationship between them.

Aggregate Measurements- measurements of several quantities of the same name carried out simultaneously, in which the desired values of the quantities are determined by solving a system of equations obtained by measuring these quantities in various combinations.

Redundant measurements(more precisely, information-redundant measurements) - measurements of several series of homogeneous physical quantities, the sizes of which are interconnected according to the law of arithmetic or geometric progression, with unchanged or standardized values of the parameters of the nonlinear (in the general case) transformation function of the sensor (or the measuring channel as a whole) , in which the desired value of a physical quantity is obtained reduced to the input of the measuring channel by processing the results of intermediate measurements according to the equation of redundant measurements, i.e. indirectly.

Aggregate Measurements- a special case of redundant measurements.

8.Measuring instruments: concept, classification. Characteristics of measuring equipment.

Measuring instrument- a technical device intended for measurements, having standardized metrological characteristics, reproducing and (or) storing a unit of physical quantity, the size of which is assumed to be unchanged (within the established error) for a known time interval.

== Classification of measuring instruments ==

By technical purpose:

*[[measure of physical quantity]]- a measuring instrument intended for reproduction and (or) storage of [[physical quantity|physical quantity]] of one or more specified dimensions, the values of which are expressed in established [[unit of measurement|units]] and are known with the required accuracy;

* [[measuring device]]- a measuring instrument designed to obtain the values of the measured physical quantity in the established range;

*[[transducer]]- a technical device with standard metrological characteristics, used to convert a measured value into another value or measuring signal, convenient for processing, storage, further transformations, indication or transmission;

* measuring setup(measuring machine) - a set of functionally combined [[measure of physical quantity|measures]], [[measuring device|measuring devices]], [[measuring transducer|measuring transducers]] and other devices, intended for measuring one or more physical quantities and located in one place

* measuring system- a set of functionally integrated [[measure of physical quantity|measures]], [[measuring device|measuring devices]], [[measuring transducer|measuring transducers]], [[computers]] and other technical means located at different points of the controlled object etc. for the purpose of measuring one or more physical quantities characteristic of this object and generating measurement signals for various purposes;

* measuring and computing complex- a functionally integrated set of measuring instruments, [[computers]] and auxiliary devices, designed to perform a specific measuring task as part of a measuring system.

By degree of [[automation|automation]]:

* automatic;

* automated;

According to [[standardization|standardization]] of measuring instruments:

* standardized;

* non-standardized.

By position in [[verification diagram|verification diagram]]:

* [[standard]]s;

* working measuring instruments.

According to the significance of the measured physical quantity:

* the main means of measuring the physical quantity whose value must be obtained in accordance with the measurement task;

* auxiliary measuring instruments of that physical quantity, the influence of which on the main measuring instrument or measurement object must be taken into account in order to obtain measurement results of the required accuracy.

According to measuring physics - chemical parameters:

* for measuring temperature;

* pressure;

* consumption and quantity;

* solution concentration;

* for level measurement, etc.

9. Verification and calibration tools: concept, classification, verification procedure.

Verification of measuring instruments- a set of operations performed by bodies of the State Metrological Service (other authorized bodies, organizations) in order to determine and confirm the compliance of measuring instruments with established technical requirements.

Calibration of measuring instruments

The subordination of the measuring instruments involved in the transfer of the unit size from the standard to the RSI is established in the testing schemes of the measuring instruments.

Verification diagram– this is a document containing the rules for transferring the unit size from the standard to working measuring instruments.

Calibration of the measuring instrument- a set of operations performed to determine and confirm the actual values of metrological characteristics and (or) suitability for use of a measuring instrument that is not subject to state metrological control and supervision.

calibration performs two functions:

· determination and confirmation of actual values of metrological characteristics of measuring instruments;

· determination and confirmation of the suitability of measuring instruments for use.

Calibration can be entrusted to both the MS of a legal entity and any other organization capable of performing calibration work. The results of SI calibration are certified by a calibration mark applied to the SI, an entry in operational documents, or a calibration certificate.

10. Standardized metrological characteristics of measuring instruments: concept, classification.

Standardized metrological characteristics of the type of measuring instruments- the most rational set of metrological characteristics of a specific type of measuring instruments, established by regulatory and technical documents.

Related information.

Send your good work in the knowledge base is simple. Use the form below

Students, graduate students, young scientists who use the knowledge base in their studies and work will be very grateful to you.

Posted on http://www.allbest.ru/

1. Subjects of metrology

metrology standard measurement

Subjects of metrology are legal entities and individuals carrying out metrological activities. These include international and regional metrology organizations, as well as metrological services (state and legal entities).

Metrological service is a structural unit of the central apparatus of the federal executive body and/or its territorial body, a legal entity or a structural unit of a legal entity or an association of legal entities, employees of a legal entity, organizing and/or performing work and/or providing services to ensure the uniformity of measurements. individual entrepreneur .

There are three levels of metrology subjects: international, regional and national (Fig. 1).

The international level is represented by international metrological organizations, which include representatives of national metrology organizations, and the regional level by metrological organizations of countries in a certain region of the globe. The national metrology level has two sublevels:

* state;

* services of legal entities.

The state sublevel of metrology includes Rostekhregulirovanie, scientific metrology centers (NMC) and standardization and metrology centers (TSSM). Each group of subjects at the national sub-level has certain functions and areas of competence.

Rostekhregulirovanie (Federal Service for Technical Regulation and Metrology) carries out state management of ensuring the uniformity of measurements. His competence includes:

* submission to the Government of the Russian Federation of proposals on units of quantities allowed for use;

* establishing rules for the creation, approval, storage and use of standards of units of quantities;

* determination of general metrological requirements for means, methods and results of measurements;

* implementation of state metrological control and supervision,

* monitoring compliance with the terms of international treaties of the Russian Federation on the recognition of test results and verification of measuring instruments;

Rice. 1. Structure of metrology subjects

CIPM - International Committee of Weights and Measures, BIPM - International Bureau of Weights and Measures, OIML - International Organization of Legal Metrology, ISO - International Organization for Standardization, TC - Technical Committee, SSMC - State Scientific Metrological Centers, RKS - - Russian calibration service, MSO - metrological service of industries, SME - metrological service of enterprises, TsSM - center for standardization and metrology

* management of the activities of the State Metrological Service and other state services to ensure the uniformity of measurements;

* participation in the activities of international organizations on issues of ensuring the uniformity of measurements.

The State Metrological Service is under the jurisdiction of Rostechregulirovanie and includes:

* state scientific metrological centers (SSMC);

* bodies of the State Metrological Service in the regions of Russia.

SSMC is represented by the State Service for Time, Frequency and Determination of Earth Rotation Parameters (GSVP), the State Service for Standard Samples, Composition and Properties of Substances and Materials (GSSO) and the State Service for Standard Reference Data on Physical Constants and Properties of Substances and Materials (GSSSD). The management and coordination of their activities is carried out by Rostekhregulirovanie.

SSMC are responsible for the creation, improvement, storage and application of state standards of units of quantities, as well as for the development of regulatory documents to ensure the uniformity of measurements

The bodies of the State Metrological Service include CSMs that carry out state metrological control and supervision in all regions of Russia.

The metrological service of legal entities is represented by the metrological services of federal government bodies and enterprises (SMEs) that are legal entities (Law on Ensuring the Uniformity of Measurements). Metrological services in government agencies and enterprises are created, if necessary, in the prescribed manner to carry out work to ensure the uniformity and required accuracy of measurements, as well as to carry out metrological control and supervision. When performing work in areas where verification of measuring instruments is necessary, the creation of metrological services and other organizational structures to ensure the uniformity of measurements is mandatory.

Metrological services of legal entities carry out metrological control by calibrating measuring instruments, monitoring the condition and use of measuring instruments, certified measurement methods, standards of units of quantities used for calibration of measuring instruments, as well as compliance with established metrological rules and norms. In addition, they check the timeliness of submission of measuring instruments for testing in order to approve the type of measuring instruments, as well as for verification and calibration.

2. Verification and calibration tools

Measuring instruments used in the areas of state metrological control are subject to verification upon release from production and repair, upon import, during operation and sale.

Verification is the establishment of the suitability of measuring instruments for use on the basis of experimentally determined metrological characteristics and monitoring their compliance with established requirements.

There are state and departmental verification, as well as primary verification (when released from production, after repair, when imported from abroad) and periodically carried out at set intervals. Periodic verifications are established based on the serviceability of the measuring instruments between verifications. It is possible to carry out extraordinary and inspection verifications.

Extraordinary verification is carried out, regardless of the period of periodic verification, when it is necessary to ensure the serviceability of the measuring instruments. Extraordinary verification is carried out during control of the verification process, if the verification mark is damaged.

Inspection verification is carried out during a metrological audit. The check is carried out by the metrological service. Verification measurements are carried out under normal conditions, which are regulated by GOST 8.395-80 - Normal conditions for verification. General requirements. Verification is one of the links in transferring the unit size from the standard to the working measuring instruments.

The body of the state metrological service carries out accreditation for the right to conduct verification. By decision of the state standard, the right of verification may be granted to other organizations, subject to their accreditation for the right of verification. The accreditation procedure is established by the state standard. Verification is carried out by persons certified as verifiers by the state metrological service.

Verification is divided into 3 parts: metrological, technical and administrative. During metrological verification the following is established:

the main error of the device;

stability, repeatability and drift;

sensitivity to electromagnetic interference, resolution of reading devices, etc.

During technical verification, the following is carried out: verification of the general condition of measuring instruments, detection of dirt, wear, correct installation of measuring instruments, assessment of the possibility of obtaining incorrect measurements due to deliberate misuse.

During administrative verification, the presence of a verification mark or verification certificate, the date of the previous verification, the integrity of brands, locks and other devices, and the availability of documents (verification protocols, repairs) are checked.

Primary verification is carried out to ensure compliance of the introduced measuring instruments with the approved type. Subsequent verification is carried out in order to establish the suitability for use of measuring instruments in operation and confirm or remove this status. Primary verification can be carried out on the territory of the manufacturer, user, state metrological service body or independent organization. The place of verification is determined by the manufacturer, trading organization or user.

Primary verification can be carried out in stages, for example: part of the verification can be carried out before installation, and part after installation of the measuring instrument at the site of operation. As a rule, each copy of the SI is subject to primary verification. For the simplest measuring instruments produced in mass production, selective verification is allowed. If the results of random verification are positive, all measuring instruments from the verified batch are marked with a verification mark. Each sample of measuring instruments or the corresponding sample of a given set of measuring instruments must undergo subsequent verification. Each measuring instrument is subjected to periodic verification after a certain number of measurements since the last verification or at certain time intervals. State metrological service bodies are obliged to take into account the results of subsequent verifications and develop recommendations for adjusting the verification interval. The result is confirmation of the suitability of the measuring instruments for use in areas subject to state metrological control, or recognition of the measuring instruments as unsuitable. If the verification results are positive, a verification mark is applied to the measuring instrument and (or) a certificate is issued - a verification certificate. For unsuitable measuring instruments, the certificate and the stamp of the verification mark are canceled and a certificate of unsuitability is issued. Bodies of the state metrological service must ensure control of the verification process. During control, the rules and methods of verification, the personnel conducting verification, standards and auxiliary equipment, verification intervals, time and place of verification, etc. are checked.

Calibration of measuring instruments is a set of operations performed to determine and confirm the actual values of metrological characteristics and / or suitability for use of measuring instruments that are not subject to state metrological control and supervision. The suitability of a measuring instrument means the compliance of its metrological characteristics with previously established technical requirements, which may be contained in a regulatory document or determined by the customer. The determination of suitability is made by the calibration laboratory.

Calibration replaced the departmental verification and metrological certification of measuring instruments that previously existed in our country. Unlike verification, which is carried out by state metrological service bodies, calibration can be carried out by any metrological service (or individual) if there are appropriate conditions for the qualified performance of this work. Calibration is a voluntary operation and can also be performed by the metrological service of the enterprise itself. This is another difference from verification, which, as mentioned above, is mandatory and is subject to control by the State Migration Service.

However, the voluntary nature of calibration does not relieve the enterprise’s metrological service from the need to comply with certain requirements. The main one is traceability, i.e. mandatory “linking” of the working measuring instrument to the national (state) standard. Therefore, the calibration function should be considered as an integral part of the national system for ensuring the uniformity of measurements. And if we take into account that the principles of the national system for ensuring the uniformity of measurements are harmonized with international rules and regulations, then calibration is included in the global system for ensuring the uniformity of measurements.

Fulfillment of this requirement (“linking” to the standard) is also important from another point of view: measurements are an integral part of technological processes, i.e. they directly affect product quality. In this regard, measurement results must be comparable, which is achieved only by transferring unit sizes from state standards and compliance with the norms and rules of legal metrology. Confidence in the product seller is supported by certificates of calibration of measuring instruments issued on behalf of a reputable national metrological organization.

The introduction of calibration in Russia has its own characteristics. In Western countries, calibration work expanded and developed, growing out of the needs to increase the competitiveness of products, and at the same time, a rather limited range of measuring instruments was subject to verification (as a mandatory function). In Russia, calibration is a product of the denationalization of processes for monitoring the serviceability of devices. And, consequently, the rejection of the universal obligation of verification brought to life the function of calibration. This process of liberalization of metrological control is not welcomed by everyone and does not go smoothly. Metrologists of both the State Metrological Service and metrological services of enterprises have to move from familiar forms of interaction, worked out over decades, to new relationships, which often causes a negative reaction.

The introduction of calibration is objectively hampered by the lack of competition. There is a certain contradiction here. On the one hand, enterprises, in accordance with the law, have the right to independently organize the calibration of measuring instruments and are not interested (in the absence of competition) in being accredited by the competent accreditation bodies for the right to carry out calibration work. On the other hand, enterprises understand that isolation from the state system of transferring unit sizes from state standards according to an established scheme to working measuring instruments can lead to a loss of accuracy and reliability of measurement results.

The following options for organizing calibration work are possible:

the enterprise independently organizes calibration work and is not accredited in any system;

an enterprise interested in increasing the competitiveness of products is accredited in the Russian Calibration System (RSC) for the right to carry out calibration work on behalf of the organization that accredited it;

the enterprise is accredited by RSK for the purpose of performing calibration work on a commercial basis;

enterprises accredited for the right to verify measuring instruments simultaneously receive an accreditation certificate for the right to carry out calibration work for the same types (areas) of measurements;

metrological institutes and bodies of the State Metrological Service are registered with the RSK simultaneously as accreditation bodies and as calibration organizations;

accreditation of the enterprise as a calibration laboratory in a foreign open calibration service.

To date, the preferred options for organizing the calibration business in Russia have not yet been determined. But we can already talk about the principles of organizing the DGC. The Russian calibration system is based on such principles as voluntary entry; mandatory transfer of unit sizes from state standards to working measuring instruments; professionalism and technical competence of DGC entities; self-sufficiency.

A standard of a unit of physical quantity is a measuring instrument or a set of measuring instruments intended for reproducing and storing units and transmitting its size to a measuring instrument lower in the verification scheme and approved as a standard in the prescribed manner.

A primary standard is a standard that reproduces a unit of physical quantity with the highest accuracy possible in a given field of measurement at the current level of scientific and technical achievements. The primary standard can be national (state) and international.

The national standard is approved as the initial measuring instrument for the country by the national metrology body. In Russia, national (state) standards are approved by the State Standard of the Russian Federation.

International standards are stored and maintained by the International Bureau of Weights and Measures (BIPM). The most important task of the BIPM is systematic international comparisons of national standards of the largest metrological laboratories in different countries with international standards, as well as with each other, which is necessary to ensure reliability, accuracy and uniformity of measurements as one of the conditions for international economic relations. Both standards of basic quantities of the SI system and derivatives are subject to comparison. Certain comparison periods have been established. For example, meter and kilogram standards are compared every 25 years, and electrical and light standards - once every 3 years.

Secondary and working (discharge) standards are subordinate to the primary standard. The size of the reproduced unit is compared with the state standard using a secondary standard. Secondary standards (they are sometimes called “copy standards”) can be approved either by the State Standard of the Russian Federation or by state scientific metrological centers, which is due to the peculiarities of their use. Working standards receive the size of a unit from secondary standards and in turn serve to convey the size to a less accurate working standard (or standard of a lower rank) and working measuring instruments.

A verification scheme for measuring instruments is a normative document establishing the subordination of measuring instruments involved in transferring the unit size from the standard to the working measuring instruments (indicating the methods and errors during transmission).

To ensure the correct transfer of the dimensions of units of measurement from the standard to the working measuring instruments, verification schemes are drawn up that establish metrological subordination of the state standard, digit standards and working measuring instruments.

Verification schemes are divided into state and local. State verification schemes apply to all measuring instruments of this type used in the country. Local verification schemes are intended for metrological bodies of ministries; they also apply to measuring instruments of subordinate enterprises. In addition, a local diagram can be drawn up for the measuring instruments used at a particular enterprise. All local verification schemes must comply with the requirements of subordination, which are determined by the state verification scheme (Fig. 31.2). State verification schemes are developed by research institutes of the State Standard of the Russian Federation, holders of state standards.

In some cases, it may be impossible to reproduce the entire range of values with one standard; therefore, the circuit may provide several primary standards, which together reproduce the entire measurement scale. For example, the temperature scale from 1.5 to 1*105 K is reproduced by two state standards.

State verification schemes are approved by the State Standard of the Russian Federation, and local verification schemes are approved by departmental metrological services or enterprise management.

Let us consider in general terms the contents of the state verification scheme.

The names of standards and working measuring instruments are usually placed in rectangles (for the state standard the rectangle is double-circuit). The metrological characteristics for this stage of the circuit are also indicated here. At the bottom of the diagram there are working measuring instruments, which, depending on their degree of accuracy (i.e., measurement error), are divided into five categories: highest accuracy; highest precision; high precision; average accuracy; lower accuracy. The highest accuracy is usually commensurate with the degree of error of the state standard measuring instrument. At each stage of the verification scheme, the procedure (method) for transferring the unit size is regulated. The names of verification (calibration) methods are located in ovals, which also indicate the permissible error of the verification (calibration) method. The main indicator of the reliability of the transmission of the size of a unit of quantity is the ratio of the errors of the measuring instruments between the higher and lower levels of the verification scheme. Ideally, this ratio should be 1:10, but in practice it cannot be achieved, and the minimum acceptable ratio is considered to be 1:3. The greater the value of this ratio, the less confidence in the reliability of the readings of the measuring device.

When developing specific verification schemes, it is necessary to follow the given scheme. Strict adherence to verification schemes and timely verification of discharge standards are necessary conditions for transferring reliable sizes of units of measurement to working measuring instruments.

Posted on Allbest.ru

...Similar documents

History of the development of metrology. Legal foundations of metrological activities in the Russian Federation. Legal liability for violation of regulatory requirements. Objects, measurement methods, types of control. International system of units of physical quantities.

cheat sheet, added 11/13/2008

Legal basis for metrological ensuring the uniformity of measurements. System of standards of units of physical quantities. State services for metrology and standardization in the Russian Federation. Activities of the Federal Agency for Technical Regulation and Metrology.

course work, added 04/06/2015

Theoretical foundations and main concepts of metrology. Methods for standardizing the metrological characteristics of measuring instruments, assessing the errors of instruments and measurement results. Fundamentals of ensuring the uniformity of measurements. Structure and functions of metrological services.

tutorial, added 11/30/2010

Subject and main tasks of theoretical, applied and legal metrology. Historically important stages in the development of measurement science. Characteristics of the international system of units of physical quantities. Activities of the International Committee of Weights and Measures.

abstract, added 10/06/2013

Regulation and control by the state of a number of metrology provisions. State system for ensuring the uniformity of measurements. Subjects of metrology. Management of three government help desks. Voluntary and mandatory certification.

test, added 01/21/2009

Metrological support for construction. A system for the development, production and release of measuring instruments that ensure the determination of product characteristics with the required accuracy. Current state of metrology in construction.

abstract, added 09/16/2013

General provisions of the State system for ensuring the uniformity of measurements. Transfer of dimensions of units of physical quantities, their verification schemes. Methods for verifying measuring instruments. Errors of state primary and special standards, their assessment.

test, added 09.19.2015

Basic information about physical quantities, their standards. System of international units, classification of types and means of measurement. Quantitative estimates of error. Voltage and current measurement. Purpose of a voltmeter, oscilloscope and digital frequency meter.

cheat sheet, added 06/14/2012

Fundamentals, goals, objectives and functions of standardization. Categories and types of standards, the procedure for their development. Standardization bodies and services. Metrological concepts. Classification of measurements. The role of metrology. Certification issues in the laws of the Russian Federation.

abstract, added 01/09/2009

Main activities of legal metrology, areas of application of its rules. Contents and goals of the Federal Law "On Ensuring the Uniformity of Measurements". Legal basis and principles of standardization. Directions of state policy in this area.

The object of metrology is physical quantities. The concept of “physical quantity” in metrology, as in physics, is understood as a property of physical objects (systems) that is qualitatively common to many objects, but quantitatively individual for each object, i.e. a property that can exist for one object one or another number of times greater or less than for another (for example, length, mass, density, temperature, force, speed). The quantitative content of the property corresponding to the concept of “physical quantity” in a given object is the size of the physical quantity.

A set of quantities interconnected by dependencies forms a system of physical quantities. Objectively existing relationships between physical quantities are represented by a series of independent equations. The number of equations m is always less than the number of quantities n. Therefore, m quantities of a given system are determined through other quantities, and n – m quantities – independently of others. The latter quantities are usually called basic physical quantities, and the rest – derived physical quantities.

The presence of a number of systems of units of physical quantities, as well as a significant number of non-system units, inconveniences associated with recalculation when moving from one system of units to another, required the unification of units of measurement. The growth of scientific, technical and economic ties between different countries necessitated such unification on an international scale.

A unified system of units of physical quantities was required, practically convenient and covering various areas of measurement. At the same time, it had to preserve the principle of coherence (equality to unity of the coefficient of proportionality in the equations of connection between physical quantities).

In Russia, GOST 8.417-2002 is in force, which prescribes the mandatory use of SI. It lists the units of measurement, gives their Russian and international names and establishes the rules for their use. According to these rules, only international designations are allowed to be used in international documents and on instrument scales. In internal documents and publications, you can use either international or Russian designations (but not both at the same time).

Derived units of the International System of Units are formed using the simplest equations between quantities in which the numerical coefficients are equal to one. Thus, for linear speed, as a defining equation, you can use the expression for the speed of uniform motion v = l/ t.

With the length of the path traveled (in meters) and time t, during which this path is covered (in seconds), the speed is expressed in meters per second (m/s). Therefore, the SI unit of speed - meter per second - is the speed of a rectilinearly and uniformly moving point at which it, in time t c moves a distance of 1 m.

Subjects of metrology:

– state metrological service;

– metrological services of federal executive authorities and legal entities;

– metrological organizations.

The subjects of metrology include: 1) State Metrological Service of the Russian Federation (SMS); 2) metrological services of federal executive authorities and legal entities (MS); 3) international metrological organizations.

State Metrological Service is under the jurisdiction of Gosstandart and includes:

state scientific metrology centers (SSMC);

State Migration Service bodies in the constituent entities of the Russian Federation (on the territory of republics, autonomous regions, autonomous okrugs, territories, regions), as well as the cities of Moscow and St. Petersburg.

State scientific metrology centers are represented by such institutes as the All-Russian Research Institute of Metrological Service (VNIIMS, Moscow), the All-Russian Research Institute of Metrology named after D. I. Mendeleev (VNIIM, St. Petersburg); NPO “VNII of physical-technical and radio-technical measurements” (VNIIFTRI, Mendeleevo village, Moscow region); Ural Research Institute of Metrology (UNIIM, Yekaterinburg), etc. These scientific centers are engaged not only in the development of scientific and methodological foundations for improving the Russian measurement system, but are also holders of state standards.

In Russia there are more than 100 CMS (respectively their metrological divisions), which perform the functions of regional HMS bodies in the territories of the constituent entities of the Russian Federation, the cities of Moscow and St. Petersburg.

Gosstandart manages three state reference services: the State Service for Time, Frequency and Determination of Earth Rotation Parameters (GSVC), the State Service for Standard Samples of the Composition and Properties of Substances and Materials (GSSO) and the State Service for Standard Reference Data on Physical Constants and Properties of Substances and Materials ( GSSSD).

GSVCH carries out interregional and intersectoral coordination of work to ensure the uniformity of measurements of time, frequency and determination of the parameters of the Earth's rotation. The average resident of the country learns about this service twice a year - during the transition to summer and winter time. Consumers of GSHF measurement information are navigation and control services for aircraft, ships and satellites, the Unified Energy System, etc.

GSSO ensures the creation and application of this. topics of standard (reference) samples of the composition and properties of substances and materials - metals and alloys, petroleum products, medical preparations, soil samples, samples of hardness of various materials, samples of gases and gas mixtures, etc. The practical significance of RM is shown above.

GSSD ensures the development of reliable data on physical constants, on the properties of substances and materials, including structural materials, mineral raw materials, oil, gas, etc. Consumers of GSSD information are organizations designing equipment products, the accuracy of the characteristics of which is subject to particularly stringent requirements. Designers This technique cannot rely on conflicting information about property values contained in the reference literature.

Metrological services of federal executive authorities and legal entities can be created in ministries (departments), organizations, enterprises and institutions that are legal entities to carry out work to ensure the uniformity and required accuracy of measurements, carry out metrological control and supervision.

When performing work in the areas provided for in Art. 13 of the Law of the Russian Federation, the creation of MS to ensure uniformity of measurements is mandatory. Thus, MGs were created in the Ministry of Health, the Ministry of Atomic Energy, the Ministry of Natural Resources, the Ministry of Defense Industry and other federal executive bodies. MS operate in RAO UES of Russia, RAO Gazprom, NK YUKOS, NK Lukoil.

The rights and obligations of the MS are determined by the provisions on them, approved by the heads of management bodies or legal entities.

If at fairly large enterprises (in legally approved areas) full-fledged MSs are organized, then at small enterprises Gosstandart recommends appointing persons responsible for ensuring the uniformity of measurements. A job description is approved for responsible persons, which establishes their functions, rights, duties and responsibilities.

International metrological organizations have been operating since the end of the 19th century. As noted above, in 1875, 17 states, including Russia, signed in Paris. The Metric Convention, which was essentially the first international standard. At the same time, the first international metrological institution was created - the International Bureau of Weights and Measures (BIPM), which is still actively functioning, coordinating the activities of metrological organizations in more than 100 countries. The BIPM is located in France, in the city of Sèvres. The BIPM stores international prototypes of the meter and kilogram and some other standards, and also organizes periodic comparisons of national standards with international ones. The management of the BIPM's activities is carried out by the International Committee of Weights and Measures (CIPM), created simultaneously with the BIPM.

On average, once every 4 years the General Conference on Weights and Measures meets, making general decisions that are most important for the development of metrology and measuring technology.

In 1956, the International Organization of Legal Metrology (OILM) was established, whose members (as of 1998) are 85 countries. OIML develops general issues of legal metrology: establishment of SI accuracy classes; ensuring uniformity of certain types, samples and systems of measuring instruments; recommendations for their testing in order to establish the uniformity of metrological characteristics of measuring instruments regardless of the country of manufacture; procedure for verification and calibration of measuring instruments, etc.

During the period 1996-1997. The metrological institutes of Gosstandart maintained 3 TCs, 12 PCs of the OIML and ISO. These TCs and PCs carried out the development of 16 draft international documents authored by Russia.

Russia participates in the Organization for Cooperation of State Metrological Institutions of Central and Eastern Europe (COOMET). Russian organizations lead or participate in the implementation of 60% of COOMET topics.

The results of many years of activity of international organizations are very effective. Thanks to their efforts, most countries of the world have adopted the International System of Units of Physical Quantities (SI), comparable terminology is in place, recommendations have been adopted on methods for standardizing the metrological characteristics of SI, on SI certification, and on SI testing before the release of serial products.

In its activities, the State Migration Service of Russia has to take into account the documents of regional international metrological organizations, as well as foreign national metrological organizations of the USA, Great Britain, etc.

Literary and historical notes of a young technician

Literary and historical notes of a young technician Collection of basic formulas for a school chemistry course

Collection of basic formulas for a school chemistry course Methods of studying history and modern historical science Classical and modern Russian historical science

Methods of studying history and modern historical science Classical and modern Russian historical science