Under normal conditions, calcium reacts with. Calcium and its characteristics

Calcium

CALCIUM-I; m.[from lat. calx (calcis) - lime] Chemical element (Ca), a silver-white metal that is part of limestone, marble, etc.

◁ Calcium, oh, oh. K salts.

calcium(lat. Calcium), a chemical element of group II of the periodic table, belongs to the alkaline earth metals. Name from lat. calx, genitive calcis - lime. Silver-white metal, density 1.54 g/cm 3, t pl 842ºC. At ordinary temperatures it is easily oxidized in air. In terms of prevalence in the earth's crust, it ranks 5th (minerals calcite, gypsum, fluorite, etc.). As an active reducing agent, it is used to obtain U, Th, V, Cr, Zn, Be and other metals from their compounds, to deoxidize steels, bronzes, etc. It is part of antifriction materials. Calcium compounds are used in construction (lime, cement), calcium preparations are used in medicine.

CALCIUMCALCIUM (lat. Calcium), Ca (read “calcium”), a chemical element with atomic number 20, is located in the fourth period in group IIA of Mendeleev’s periodic system of elements; atomic mass 40.08. Belongs to the alkaline earth elements (cm. ALKALINE EARTH METALS).

Natural calcium consists of a mixture of nuclides (cm. NUCLIDE) with mass numbers of 40 (in a mixture by mass of 96.94%), 44 (2.09%), 42 (0.667%), 48 (0.187%), 43 (0.135%) and 46 (0.003%). Outer electron layer 4 configuration s 2

. In almost all compounds, the oxidation state of calcium is +2 (valency II).

The radius of the neutral calcium atom is 0.1974 nm, the radius of the Ca 2+ ion is from 0.114 nm (for coordination number 6) to 0.148 nm (for coordination number 12). The energies of sequential ionization of a neutral calcium atom are, respectively, 6.133, 11.872, 50.91, 67.27 and 84.5 eV. According to the Pauling scale, the electronegativity of calcium is about 1.0. In its free form, calcium is a silvery-white metal.

History of discovery

Calcium compounds are found everywhere in nature, so humanity has been familiar with them since ancient times. Lime has long been used in construction (cm. LIME)(quicklime and slaked), which has long been considered a simple substance, “earth.” However, in 1808 the English scientist G. Davy (cm. DAVY Humphrey) managed to obtain a new metal from lime. To do this, Davy subjected to electrolysis a mixture of slightly moistened slaked lime with mercury oxide and isolated a new metal from the amalgam formed on the mercury cathode, which he called calcium (from the Latin calx, genus calcis - lime). In Russia for some time this metal was called “liming”.

Being in nature

Calcium is one of the most common elements on Earth. It accounts for 3.38% of the mass of the earth's crust (5th most abundant after oxygen, silicon, aluminum and iron). Due to its high chemical activity, calcium does not occur in free form in nature. Most calcium is found in silicates (cm. SILICATES) and aluminosilicates (cm. ALUMINUM SILICATES) various rocks (granites (cm. GRANITE), gneisses (cm. GNEISS) and so on.). In the form of sedimentary rocks, calcium compounds are represented by chalk and limestones, consisting mainly of the mineral calcite (cm. CALCITE)(CaCO 3). The crystalline form of calcite - marble - is much less common in nature.

Calcium minerals such as limestone are quite common (cm. LIMESTONE) CaCO3, anhydrite (cm. ANHYDRITE) CaSO 4 and gypsum (cm. GYPSUM) CaSO 4 2H 2 O, fluorite (cm. FLUORITE) CaF 2, apatites (cm. APATITE) Ca 5 (PO 4) 3 (F,Cl,OH), dolomite (cm. DOLOMITE) MgCO 3 ·CaCO 3 . The presence of calcium and magnesium salts in natural water determines its hardness (cm. HARDNESS OF WATER). A significant amount of calcium is found in living organisms. Thus, hydroxyapatite Ca 5 (PO 4) 3 (OH), or, in another entry, 3Ca 3 (PO 4) 2 ·Ca(OH) 2, is the basis of the bone tissue of vertebrates, including humans; The shells and shells of many invertebrates, eggshells, etc. are made from calcium carbonate CaCO 3.

Receipt

Metallic calcium is obtained by electrolysis of a melt consisting of CaCl 2 (75-80%) and KCl or from CaCl 2 and CaF 2, as well as aluminothermic reduction of CaO at 1170-1200 °C:

4CaO + 2Al = CaAl 2 O 4 + 3Ca.

Physical and chemical properties

Calcium metal exists in two allotropic modifications (see Allotropy (cm. ALLOTROPY)). Up to 443 °C, a-Ca with a cubic face-centered lattice (parameter a = 0.558 nm) is stable; b-Ca with a cubic body-centered lattice of the a-Fe type (parameter a = 0.448 nm) is more stable. Melting point of calcium is 839 °C, boiling point is 1484 °C, density is 1.55 g/cm3.

The chemical activity of calcium is high, but lower than that of all other alkaline earth metals. It easily reacts with oxygen, carbon dioxide and moisture in the air, which is why the surface of calcium metal is usually dull gray, so in the laboratory calcium is usually stored, like other alkaline earth metals, in a tightly closed jar under a layer of kerosene.

In the series of standard potentials, calcium is located to the left of hydrogen. The standard electrode potential of the Ca 2+ /Ca 0 pair is –2.84 V, so that calcium actively reacts with water:

Ca + 2H 2 O = Ca(OH) 2 + H 2.

Calcium reacts with active non-metals (oxygen, chlorine, bromine) under normal conditions:

2Ca + O 2 = 2CaO; Ca + Br 2 = CaBr 2.

When heated in air or oxygen, calcium ignites. Calcium reacts with less active non-metals (hydrogen, boron, carbon, silicon, nitrogen, phosphorus and others) when heated, for example:

Ca + H 2 = CaH 2 (calcium hydride),

Ca + 6B = CaB 6 (calcium boride),

3Ca + N 2 = Ca 3 N 2 (calcium nitride)

Ca + 2C = CaC 2 (calcium carbide)

3Ca + 2P = Ca 3 P 2 (calcium phosphide), calcium phosphides of the compositions CaP and CaP 5 are also known;

2Ca + Si = Ca 2 Si (calcium silicide); calcium silicides of the compositions CaSi, Ca 3 Si 4 and CaSi 2 are also known.

The occurrence of the above reactions, as a rule, is accompanied by the release of a large amount of heat (i.e., these reactions are exothermic). In all compounds with non-metals, the oxidation state of calcium is +2. Most of the calcium compounds with non-metals are easily decomposed by water, for example:

CaH 2 + 2H 2 O = Ca(OH) 2 + 2H 2,

Ca 3 N 2 + 3H 2 O = 3Ca(OH) 2 + 2NH 3.

Calcium oxide is typically basic. In the laboratory and technology it is obtained by thermal decomposition of carbonates:

CaCO 3 = CaO + CO 2.

Technical calcium oxide CaO is called quicklime.

It reacts with water to form Ca(OH) 2 and release a large amount of heat:

CaO + H 2 O = Ca(OH) 2.

Ca(OH)2 obtained in this way is usually called slaked lime or milk of lime (cm. LIME MILK) due to the fact that the solubility of calcium hydroxide in water is low (0.02 mol/l at 20°C), and when it is added to water, a white suspension is formed.

When interacting with acidic oxides, CaO forms salts, for example:

CaO + CO 2 = CaCO 3; CaO + SO 3 = CaSO 4.

The Ca 2+ ion is colorless. When calcium salts are added to the flame, the flame turns brick-red.

Calcium salts such as CaCl 2 chloride, CaBr 2 bromide, CaI 2 iodide and Ca(NO 3) 2 nitrate are highly soluble in water. Insoluble in water are fluoride CaF 2, carbonate CaCO 3, sulfate CaSO 4, average orthophosphate Ca 3 (PO 4) 2, oxalate CaC 2 O 4 and some others.

It is important that, unlike the average calcium carbonate CaCO 3, acidic calcium carbonate (bicarbonate) Ca(HCO 3) 2 is soluble in water. In nature, this leads to the following processes. When cold rain or river water, saturated with carbon dioxide, penetrates underground and falls on limestone, their dissolution is observed:

CaCO 3 + CO 2 + H 2 O = Ca(HCO 3) 2.

In the same places where water saturated with calcium bicarbonate comes to the surface of the earth and is heated by the sun's rays, a reverse reaction occurs:

Ca(HCO 3) 2 = CaCO 3 + CO 2 + H 2 O.

This is how large masses of substances are transferred in nature. As a result, huge holes can form underground (see Karst (cm. KARST (natural phenomenon))), and beautiful stone “icicles” - stalactites - form in the caves (cm. STALACTITES (mineral formations)) and stalagmites (cm. STALAGMITES).

The presence of dissolved calcium bicarbonate in water largely determines the temporary hardness of water. (cm. HARDNESS OF WATER). It is called temporary because when water boils, bicarbonate decomposes and CaCO 3 precipitates. This phenomenon leads, for example, to the fact that scale forms in the kettle over time.

Application of calcium and its compounds

Calcium metal is used for metallothermic production of uranium (cm. URANIUM (chemical element)), thorium (cm. THORIUM), titanium (cm. TITANIUM (chemical element)), zirconium (cm. ZIRCONIUM), cesium (cm. CESIUM) and rubidium (cm. RUBIDIUM).

Natural calcium compounds are widely used in the production of binders (cement (cm. CEMENT), gypsum (cm. GYPSUM), lime, etc.). The binding effect of slaked lime is based on the fact that over time, calcium hydroxide reacts with carbon dioxide in the air. As a result of the ongoing reaction, needle-shaped crystals of calcite CaCO3 are formed, which grow into nearby stones, bricks, and other building materials and, as it were, weld them into a single whole. Crystalline calcium carbonate - marble - is an excellent finishing material. Chalk is used for whitewashing. Large quantities of limestone are consumed in the production of cast iron, as they make it possible to convert refractory impurities of iron ore (for example, quartz SiO 2) into relatively low-melting slags.

Bleach is very effective as a disinfectant. (cm. BLEACHING POWDER)- “bleach” Ca(OCl)Cl - mixed chloride and calcium hypochloride (cm. CALCIUM HYPOCHLORITE), with high oxidizing ability.

Calcium sulfate is also widely used, existing both in the form of an anhydrous compound and in the form of crystalline hydrates - the so-called “semi-aqueous” sulfate - alabaster (cm. ALEVIZ FRYAZIN (Milanese)) CaSO 4 ·0.5H 2 O and dihydrate sulfate - gypsum CaSO 4 ·2H 2 O. Gypsum is widely used in construction, in sculpture, for the manufacture of stucco molding and various artistic products. Plaster is also used in medicine to fix bones during fractures.

Calcium chloride CaCl 2 is used along with table salt to combat icing of road surfaces. Calcium fluoride CaF 2 is an excellent optical material.

Calcium in the body

Calcium is a biogenic element (cm. BIOGENIC ELEMENTS), constantly present in the tissues of plants and animals. An important component of the mineral metabolism of animals and humans and the mineral nutrition of plants, calcium performs various functions in the body. Composed of apatite (cm. APATITE), as well as sulfate and carbonate, calcium forms the mineral component of bone tissue. The human body weighing 70 kg contains about 1 kg of calcium. Calcium participates in the functioning of ion channels (cm. ION CHANNELS) transporting substances through biological membranes in the transmission of nerve impulses (cm. NERVOUS IMPULSE), in blood clotting processes (cm. BLOOD CLOTTING) and fertilization. Calciferols regulate calcium metabolism in the body (cm. CALCIFEROLS)(vitamin D). Lack or excess of calcium leads to various diseases - rickets (cm. RICKETS), calcinosis (cm. CALCINOSIS) etc. Therefore, human food must contain calcium compounds in the required quantities (800-1500 mg of calcium per day). Calcium content is high in dairy products (such as cottage cheese, cheese, milk), some vegetables and other foods. Calcium preparations are widely used in medicine.

encyclopedic Dictionary. 2009 .

Synonyms:Introduction

Properties and uses of calcium

1 Physical properties

2 Chemical properties

3 Application

Getting calcium

1 Electrolytic production of calcium and its alloys

2 Thermal production

3 Vacuum-thermal method for obtaining calcium

3.1 Aluminothermic method for calcium reduction

3.2 Silicothermic method for calcium reduction

Practical part

Bibliography

Introduction

Chemical element of group II of the periodic system of Mendeleev, atomic number 20, atomic mass 40.08; silver-white light metal. The natural element is a mixture of six stable isotopes: 40Ca, 42Ca, 43Ca, 44Ca, 46Ca and 48Ca, of which the most common is 40 Ca (96, 97%).

Ca compounds - limestone, marble, gypsum (as well as lime - a product of calcination of limestone) were already used in construction in ancient times. Until the end of the 18th century, chemists considered lime to be a simple solid. In 1789, A. Lavoisier suggested that lime, magnesia, barite, alumina and silica are complex substances. In 1808, G. Davy, subjecting a mixture of wet slaked lime with mercury oxide to electrolysis with a mercury cathode, prepared a Ca amalgam, and by distilling mercury from it, he obtained a metal called “Calcium” (from the Latin calx, gender calcis - lime) .

The ability of calcium to bind oxygen and nitrogen has made it possible to use it for the purification of inert gases and as a getter (Getter is a substance used to absorb gases and create a deep vacuum in electronic devices.) in vacuum radio equipment.

Calcium is also used in the metallurgy of copper, nickel, special steels and bronzes; they bind harmful impurities of sulfur, phosphorus, and excess carbon. For the same purposes, calcium alloys with silicon, lithium, sodium, boron, and aluminum are used.

In industry, calcium is obtained in two ways:

) By heating the briquetted mixture of CaO and Al powder at 1200 °C in a vacuum of 0.01 - 0.02 mm. rt. Art.; distinguished by reaction:

CaO + 2Al = 3CaO Al2O3 + 3Ca

Calcium vapor condenses on a cold surface.

) By electrolysis of a melt of CaCl2 and KCl with a liquid copper-calcium cathode, a Cu - Ca alloy (65% Ca) is prepared, from which calcium is distilled off at a temperature of 950 - 1000 ° C in a vacuum of 0.1 - 0.001 mm Hg.

) A method for producing calcium by thermal dissociation of calcium carbide CaC2 has also been developed.

Calcium is very common in nature in the form of various compounds. In the earth's crust it ranks fifth, accounting for 3.25%, and is most often found in the form of limestone CaCO 3, dolomite CaCO 3Mg CO 3, gypsum CaSO 42H 2O, phosphorite Ca 3(P.O. 4)2 and fluorspar CaF 2, not counting the significant proportion of calcium in the composition of silicate rocks. Sea water contains an average of 0.04% (wt.) calcium.

In this course work, the properties and uses of calcium are studied, as well as the theory and technology of vacuum-thermal methods for its production.

. Properties and uses of calcium

.1 Physical properties

Calcium is a silvery-white metal, but fades when exposed to air due to the formation of oxide on its surface. It is a ductile metal harder than lead. Crystal cell ?-Ca shape (stable at ordinary temperature) face-centered cubic, a = 5.56 Å . Atomic radius 1.97 Å , ionic radius Ca 2+, 1,04Å . Density 1.54 g/cm 3(20°C). Above 464 °C hexagonal ?-form. melting point 851 °C, boiling point 1482 °C; temperature coefficient of linear expansion 22·10 -6 (0-300 °C); thermal conductivity at 20 °C 125.6 W/(m K) or 0.3 cal/(cm sec °C); specific heat capacity (0-100 °C) 623.9 J/(kg K) or 0.149 cal/(g °C); electrical resistivity at 20 °C 4.6 10 -8ohm m or 4.6 10 -6 ohm cm; temperature coefficient of electrical resistance is 4.57·10-3 (20 °C). Modulus of elasticity 26 Gn/m 2(2600 kgf/mm 2); tensile strength 60 MN/m 2(6 kgf/mm 2); elastic limit 4 MN/m 2(0.4 kgf/mm 2), yield strength 38 MN/m 2(3.8 kgf/mm 2); relative elongation 50%; Brinell hardness 200-300 Mn/m 2(20-30 kgf/mm 2). Calcium of sufficiently high purity is plastic, easily pressed, rolled and amenable to cutting.

1.2 Chemical properties

Calcium is an active metal. So, under normal conditions, it easily interacts with atmospheric oxygen and halogens:

Ca + O 2= 2 CaO (calcium oxide) (1)

Ca + Br 2= CaBr 2(calcium bromide). (2)

Calcium reacts with hydrogen, nitrogen, sulfur, phosphorus, carbon and other non-metals when heated:

Ca + H 2= SaN 2(calcium hydride) (3)

Ca + N 2= Ca 3N 2(calcium nitride) (4)

Ca + S = CaS (calcium sulfide) (5)

Ca + 2 P = Ca 3R 2(calcium phosphide) (6)

Ca + 2 C = CaC 2 (calcium carbide) (7)

Calcium reacts slowly with cold water, but very energetically with hot water, giving the strong base Ca(OH)2 :

Ca + 2 H 2O = Ca(OH)2 + N 2 (8)

Being an energetic reducing agent, calcium can remove oxygen or halogens from oxides and halides of less active metals, i.e. it has reducing properties:

Ca + Nb 2O5 = CaO + 2 Nb; (9)

Ca + 2 NbCl 5= 5 CaCl2 + 2 Nb (10)

Calcium reacts vigorously with acids to release hydrogen, reacts with halogens and dry hydrogen to form CaH hydride 2. When calcium is heated with graphite, CaC carbide is formed. 2. Calcium is obtained by electrolysis of molten CaCl 2or aluminothermic reduction in vacuum:

6CaO + 2Al = 3Ca + 3CaO Al2 ABOUT 3 (11)

Pure metal is used to reduce compounds of Cs, Rb, Cr, V, Zr, Th, U to metals, and for deoxidation of steels.

1.3 Application

Calcium is increasingly being used in various industries. Recently, it has gained great importance as a reducing agent in the preparation of a number of metals.

Pure metal. Uranium is obtained by reducing uranium fluoride with calcium metal. Calcium or its hydrides can be used to reduce titanium oxides, as well as oxides of zirconium, thorium, tantalum, niobium, and other rare metals.

Calcium is a good deoxidizer and degasser in the production of copper, nickel, chromium-nickel alloys, special steels, nickel and tin bronzes; it removes sulfur, phosphorus, and carbon from metals and alloys.

Calcium forms refractory compounds with bismuth, so it is used to purify lead from bismuth.

Calcium is added to various light alloys. It helps improve the ingot surface, fine grain size and reduce oxidation.

Bearing alloys containing calcium are widely used. Lead alloys (0.04% Ca) can be used to make cable sheaths.

Antifriction alloys of calcium and lead are used in technology. Calcium minerals are widely used. Thus, limestone is used in the production of lime, cement, sand-lime brick and directly as a building material, in metallurgy (flux), in the chemical industry for the production of calcium carbide, soda, caustic soda, bleach, fertilizers, in the production of sugar, glass.

Chalk, marble, Iceland spar, gypsum, fluorite, etc. are of practical importance. Due to the ability to bind oxygen and nitrogen, calcium or calcium alloys with sodium and other metals are used for the purification of noble gases and as a getter in vacuum radio equipment. Calcium is also used to produce hydride, which is a source of hydrogen in the field.

2. Getting calcium

There are several ways to obtain calcium, these are electrolytic, thermal, vacuum-thermal.

.1 Electrolytic production of calcium and its alloys

The essence of the method is that the cathode initially touches the molten electrolyte. At the point of contact, a liquid drop of metal is formed that well wets the cathode, which, when the cathode is slowly and evenly raised, is removed from the melt along with it and solidifies. In this case, the solidified drop is covered with a solid film of electrolyte, protecting the metal from oxidation and nitriding. By continuously and carefully lifting the cathode, the calcium is drawn into rods.

2.2 Thermal production

calcium chemical electrolytic thermal

· Chloride process: The technology consists of melting and dehydrating calcium chloride, melting lead, producing a double lead-sodium alloy, producing a ternary lead-sodium-calcium alloy and diluting the ternary alloy with lead after removing the salts. The reaction with calcium chloride proceeds according to the equation

CaCl 2 +Na 2Pb 5=2NaCl + PbCa + 2Pb (12)

· Carbide process: The basis for producing lead-calcium alloy is the reaction between calcium carbide and molten lead according to the equation

CaC 2+ 3Pb = Pb3 Ca+2C. (13)

2.3 Vacuum-thermal method for producing calcium

Raw materials for the vacuum-thermal method

The raw material for the thermal reduction of calcium oxide is lime, obtained by calcining limestone. The main requirements for raw materials are as follows: lime must be as pure as possible and contain a minimum of impurities that can be reduced and converted into metal along with calcium, especially alkali metals and magnesium. Limestone should be fired until the carbonate is completely decomposed, but not before it is sintered, since the reducibility of the sintered material is lower. The fired product must be protected from the absorption of moisture and carbon dioxide, the release of which during recovery reduces the performance of the process. The technology for calcining limestone and processing the calcined product is similar to processing dolomite for the silicothermic method of producing magnesium.

.3.1 Aluminothermic method for calcium reduction

The diagram of the temperature dependence of the change in the free energy of oxidation of a number of metals (Fig. 1) shows that calcium oxide is one of the most durable and difficult to reduce oxides. It cannot be reduced by other metals in the usual way - at relatively low temperatures and atmospheric pressure. On the contrary, calcium itself is an excellent reducing agent for other difficult-to-reduce compounds and a deoxidizing agent for many metals and alloys. Reduction of calcium oxide by carbon is generally impossible due to the formation of calcium carbides. However, due to the fact that calcium has a relatively high vapor pressure, its oxide can be reduced in vacuum by aluminum, silicon or their alloys according to the reaction

CaO + Me? Ca + MeO (14).

So far, only the aluminothermic method for producing calcium has found practical application, since it is much easier to reduce CaO with aluminum than with silicon. There are different views on the chemistry of the reduction of calcium oxide with aluminum. L. Pidgeon and I. Atkinson believe that the reaction proceeds with the formation of calcium monoaluminate:

CaO + 2Al = CaO Al 2O3 + 3Ca. (15)

V. A. Pazukhin and A. Ya. Fischer indicate that the process occurs with the formation of tricalcium aluminate:

CaO + 2Al = 3CaO Al 2O 3+ 3Ca. (16)

According to A.I. Voinitsky, the formation of pentacalcium trialuminate is predominant in the reaction:

CaO + 6Al = 5CaO 3Al 2O3 + 9Ca. (17)

The latest research by A. Yu. Taits and A. I. Voinitsky has established that the aluminothermic reduction of calcium occurs in steps. Initially, the release of calcium is accompanied by the formation of 3CaO·AI 2O 3, which then reacts with calcium oxide and aluminum to form 3CaO 3AI 2O 3. The reaction proceeds according to the following scheme:

CaO + 6Al = 2 (3CaO Al 2O 3)+ 2CaO + 2Al + 6Ca

(3CaO Al 2O 3) + 2CaO + 2Al = 5CaO 3Al 2O 3+ 3Ca

CaO+ 6A1 = 5CaO 3Al 2O 3+ 9Ca

Since the reduction of the oxide occurs with the release of vaporous calcium, and the remaining reaction products are in a condensed state, it is easy to separate and condense it in the cooled areas of the furnace. The main conditions necessary for vacuum-thermal reduction of calcium oxide are high temperature and low residual pressure in the system. Below is the relationship between temperature and equilibrium calcium vapor pressure. The free energy of reaction (17), calculated for temperatures 1124-1728° K is expressed

F T = 184820 + 6.95T-12.1 T lg T.

Hence the logarithmic dependence of the equilibrium calcium vapor pressure (mm Hg)

Lg p = 3.59 - 4430\T.

L. Pidgeon and I. Atkinson determined experimentally the equilibrium vapor pressure of calcium. A detailed thermodynamic analysis of the reaction of the reduction of calcium oxide with aluminum was carried out by I. I. Matveenko, who gave the following temperature dependences of the equilibrium pressure of calcium vapor:

Lgp Ca(1) =8.64 - 12930\T mm Hg.

Lgp Ca(2) =8.62 - 11780\T mmHg.

Lgp Ca(3 )=8.75 - 12500\T mmHg.

The calculated and experimental data are compared in Table. 1.

Table 1 - Effect of temperature on the change in the equilibrium elasticity of calcium vapor in systems (1), (2), (3), (3), mm Hg.

Temperature °СExperimental dataCalculated in systems(1)(2)(3)(3) )1401 1451 1500 1600 17000,791 1016 - - -0,37 0,55 1,2 3,9 11,01,7 3,2 5,6 18,2 492,7 3,5 4,4 6,6 9,50,66 1,4 2,5 8,5 25,7

From the data presented it is clear that the most favorable conditions are for interactions in systems (2) and (3) or (3"). This corresponds to observations, since pentacalcium trialuminate and tricalcium aluminate predominate in the residues of the charge after the reduction of calcium oxide with aluminum.

Data on equilibrium elasticity show that the reduction of calcium oxide with aluminum is possible at a temperature of 1100-1150 ° C. To achieve a practically acceptable reaction rate, the residual pressure in the Growth system must be below the equilibrium P equals , i.e. the inequality P must be observed equals >P ost , and the process must be carried out at temperatures of the order of 1200°. Research has established that at a temperature of 1200-1250°, high utilization (up to 70-75%) and low specific consumption of aluminum (about 0.6-0.65 kg per kg of calcium) are achieved.

According to the above interpretation of the chemistry of the process, the optimal composition is a charge designed to form 5CaO 3Al in the residue 2O 3. To increase the degree of aluminum utilization, it is useful to give some excess of calcium oxide, but not too much (10-20%), otherwise it will negatively affect other indicators of the process. With an increase in the degree of aluminum grinding from particles of 0.8-0.2 mm to minus 0.07 mm (according to V. A. Pazukhin and A. Ya. Fischer), the use of aluminum in the reaction increases from 63.7 to 78%.

The use of aluminum is also influenced by the charge briquetting mode. A mixture of lime and powdered aluminum should be briquetted without binders (to avoid gas evolution in a vacuum) at a pressure of 150 kg/cm3 2. At lower pressures, the use of aluminum decreases due to the segregation of molten aluminum in excessively porous briquettes, and at high pressures - due to poor gas permeability. The completeness and speed of recovery also depend on the density of the briquettes in the retort. When laying them without gaps, when the gas permeability of the entire cage is low, the use of aluminum is significantly reduced.

Figure 2 - Scheme for obtaining calcium by vacuum-thermal method.

Alumino-thermal method technology

The technological scheme for the production of calcium by the aluminothermic method is shown in Fig. 2. Limestone is used as the starting material, and aluminum powder made from primary (better) or secondary aluminum is used as a reducing agent. Aluminum used as a reducing agent, as well as raw materials, should not contain impurities of highly volatile metals: magnesium, zinc, alkalis, etc., which can evaporate and turn into condensate. This must be taken into account when choosing grades of recycled aluminum.

According to the description of S. Loomis and P. Staub, in the USA, at the New England Lime Co. plant in Canaan (Connecticut), calcium is produced by an aluminothermic method. Lime of the following typical composition is used,%: 97.5 CaO, 0.65 MgO, 0.7 SiO 2, 0.6 Fe 2Oz + AlOz, 0.09 Na 2O+K 2Oh, 0.5 is the rest. The calcined product is ground in a Raymond mill with a centrifugal separator, the grinding fineness is (60%) minus 200 mesh. Aluminum dust, which is a waste product from the production of aluminum powder, is used as a reducing agent. Burnt lime from closed bins and aluminum from drums are fed to dosing scales and then to the mixer. After mixing, the mixture is briquetted using a dry method. At the mentioned plant, calcium is reduced in retort furnaces, which were previously used to obtain magnesium by the silicothermic method (Fig. 3). The furnaces are heated with generator gas. Each furnace has 20 horizontal retorts made of heat-resistant steel containing 28% Cr and 15% Ni.

Figure 3 - Retort furnace for calcium production

Retort length 3 m, diameter 254 mm, wall thickness 28 mm. Reduction occurs in the heated part of the retort, and condensation occurs in the cooled end protruding from the speech. The briquettes are introduced into the retort in paper bags, then the capacitors are inserted and the retort is closed. Air is pumped out using mechanical vacuum pumps at the beginning of the cycle. Then diffusion pumps are connected and the residual pressure is reduced to 20 microns.

Retorts are heated to 1200°. In 12 hours. After loading, the retorts are opened and unloaded. The resulting calcium is in the form of a hollow cylinder of a dense mass of large crystals deposited on the surface of a steel sleeve. The main impurity in calcium is magnesium, which is reduced first and is mainly concentrated in the layer adjacent to the sleeve. The average impurity content is; 0.5-1% Mg, about 0.2% Al, 0.005-0.02% Mn, up to 0.02% N, other impurities - Cu, Pb, Zn, Ni, Si, Fe - occur in the range of 0.005-0.04%. A. Yu. Taits and A. I. Voinitsky used a semi-factory electric vacuum furnace with coal heaters to produce calcium by an aluminothermic method and achieved a degree of aluminum utilization of 60%, a specific aluminum consumption of 0.78 kg, a specific charge consumption of 4.35 kg, and a specific electricity consumption 14 kW/h per 1 kg of metal.

The resulting metal, with the exception of an admixture of magnesium, was distinguished by relatively high purity. On average, the content of impurities in it was: 0.003-0.004% Fe, 0.005-0.008% Si, 0.04-0.15% Mn, 0.0025-0.004% Cu, 0.006-0.009% N, 0.25% Al.

2.3.2 Silicothermic recovery method calcium

The silicothermic method is very tempting; the reducing agent is ferrosilicon, a reagent that is much cheaper than aluminum. However, the silicothermic process is more difficult to implement than the aluminothermic one. The reduction of calcium oxide by silicon proceeds according to the equation

CaO + Si = 2CaO SiO2 + 2Ca. (18)

The equilibrium vapor pressure of calcium, calculated from free energy values, is:

°С1300140015001600Р, mm Hg. st0.080.150.752.05

Therefore, in a vacuum of the order of 0.01 mm Hg. Art. reduction of calcium oxide is thermodynamically possible at a temperature of 1300°. In practice, to ensure acceptable speed, the process must be carried out at a temperature of 1400-1500°.

The reaction of reduction of calcium oxide with silicoaluminium, in which both aluminum and silicon alloys serve as reducing agents, is somewhat easier. Experiments have established that reduction with aluminum predominates at first; and the reaction proceeds with the final formation of bCaO 3Al 2Oz according to the scheme outlined above (Fig. 1). Silicon reduction becomes significant at higher temperatures when most of the aluminum has reacted; the reaction proceeds with the formation of 2CaO SiO 2. In summary, the reduction reaction of calcium oxide with silicoaluminum is expressed by the following equation:

mSi + n Al + (4m +2 ?) CaO = m(2CaO ·SiO 2) + ?n(5CaO Al 2O3 ) + (2m +1, 5n) Ca.

Research by A. Yu. Taits and A. I. Voinitsky has established that calcium oxide is reduced by 75% ferrosilicon with a metal yield of 50-75% at a temperature of 1400-1450° in a vacuum of 0.01-0.03 mm Hg. Art.; silicoaluminum containing 60-30% Si and 32-58% Al (the rest is iron, titanium, etc.), reduces calcium oxide with a metal yield of approximately 70% at temperatures of 1350-1400° in a vacuum of 0.01-0.05 mm Hg . Art. Experiments on a semi-factory scale have proven the fundamental possibility of producing calcium from lime using ferrosilicon and silicoaluminum. The main hardware difficulty is the selection of a stand under the conditions of this lining process.

When solving this problem, the method can be implemented in industry. Decomposition of calcium carbide Obtaining calcium metal by decomposition of calcium carbide

CaC2 = Ca + 2C

should be considered a promising method. In this case, graphite is obtained as a second product. V. Mauderli, E. Moser, and V. Treadwell, having calculated the free energy of formation of calcium carbide from thermochemical data, obtained the following expression for the calcium vapor pressure over pure calcium carbide:

ca = 1.35 - 4505\T (1124-1712° K),

lgp ca = 6.62 - 13523\T (1712-2000° K).

Apparently, commercial calcium carbide decomposes at much higher temperatures than follows from these expressions. The same authors report the thermal decomposition of calcium carbide in compact pieces at 1600-1800° in a vacuum of 1 mm Hg. Art. The yield of graphite was 94%, calcium was obtained in the form of a dense coating on the refrigerator. A. S. Mikulinsky, F. S. Morii, R. Sh. Shklyar to determine the properties of graphite obtained by decomposition of calcium carbide, the latter was heated in a vacuum of 0.3-1 mm Hg. Art. at a temperature of 1630-1750°. The resulting graphite differs from Acheson graphite in having larger grains, greater electrical conductivity and lower volumetric weight.

3. Practical part

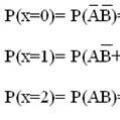

The daily discharge of magnesium from an electrolyzer at a current of 100 kA was 960 kg when feeding the bath with magnesium chloride. The voltage across the electrolyzer is 0.6 V. Determine:

)Current output at the cathode;

)The amount of chlorine produced per day, provided that the current output at the anode is equal to the current output at the anode;

)Daily filling of MgCl 2into the electrolyzer provided that the loss of MgCl 2 occur mainly with sludge and sublimation. The amount of sludge is 0.1 per 1t of Mg containing MgCl 2 in sublimate 50%. The amount of sublimation is 0.05 t per 1 t Mg. Composition of magnesium chloride being poured,%: 92 MgCl2 and 8 NaCl.

.Determine the current output at the cathode:

m etc =I ?·k Mg · ?

?=m etc \I· ?k Mg =960000\100000·0.454·24=0.881 or 88.1%

.Determine the amount of Cl received per day:

x=960000g\24g\mol=40000 mol

Converting to volume:

x=126785.7 m3

3.a) Find pure MgCl 2, to produce 960 kg Mg.

x=95·960\24.3=3753 kg=37.53 t.

b) losses with sludge. From the composition of magnesium electrolyzers, %: 20-35 MgO, 2-5 Mg, 2-6 Fe, 2-4 SiO 2, 0.8-2 TiO 2, 0.4-1.0 C, 35 MgCl2 .

kg - 1000 kg

m wow =960 kg - mass of sludge per day.

Per day 96 kg of sludge: 96·0.35 (MgCl2 with sludge).

c) losses with sublimates:

kg - 1000 kg

kg sublimates: 48·0.5=24 kg MgCl 2 with sublimates.

Total Mg you need to fill:

33.6+24=3810.6 kg MgCl2 per day

Bibliography

Fundamentals of Metallurgy III

<#"justify">metallurgy of Al and Mg. Vetyukov M.M., Tsyplokov A.M.

Tutoring

Need help studying a topic?

Our specialists will advise or provide tutoring services on topics that interest you.

Submit your application indicating the topic right now to find out about the possibility of obtaining a consultation.

Calcium is located in the fourth major period, the second group, the main subgroup, the serial number of the element is 20. According to the periodic table of Mendeleev, the atomic weight of calcium is 40.08. The formula of the highest oxide is CaO. Calcium has a Latin name calcium, so the element's atom symbol is Ca.

Characteristics of calcium as a simple substance

Under normal conditions, calcium is a silvery-white metal. Having high chemical activity, the element is capable of forming many compounds of different classes. The element is valuable for technical and industrial chemical syntheses. The metal is widespread in the earth's crust: its share is about 1.5%. Calcium belongs to the group of alkaline earth metals: when dissolved in water, it produces alkalis, but in nature it occurs in the form of multiple minerals and. Sea water contains calcium in high concentrations (400 mg/l).

Pure sodiumThe characteristics of calcium depend on the structure of its crystal lattice. This element has two types: cubic face-centric and volume-centric. The type of bond in the molecule is metallic.

Natural sources of calcium:

- apatites;

- alabaster;

- gypsum;

- calcite;

- fluorite;

- dolomite.

Physical properties of calcium and methods of obtaining the metal

Under normal conditions, calcium is in a solid state of aggregation. The metal melts at 842 °C. Calcium is a good electrical and thermal conductor. When heated, it first turns into a liquid and then into a vapor state and loses its metallic properties. The metal is very soft and can be cut with a knife. Boils at 1484 °C.

Under pressure, calcium loses its metallic properties and electrical conductivity. But then the metallic properties are restored and the properties of a superconductor appear, several times higher in their performance than the others.

For a long time it was not possible to obtain calcium without impurities: due to its high chemical activity, this element does not occur in nature in its pure form. The element was discovered at the beginning of the 19th century. Calcium as a metal was first synthesized by the British chemist Humphry Davy. The scientist discovered the peculiarities of the interaction of melts of solid minerals and salts with electric current. Nowadays, electrolysis of calcium salts (a mixture of calcium and potassium chlorides, a mixture of fluoride and calcium chloride) remains the most relevant method for producing metal. Calcium is also extracted from its oxide using aluminothermy, a common method in metallurgy.

Chemical properties of calcium

Calcium is an active metal that enters into many interactions. Under normal conditions, it easily reacts, forming the corresponding binary compounds: with oxygen, halogens. Click to learn more about calcium compounds. When heated, calcium reacts with nitrogen, hydrogen, carbon, silicon, boron, phosphorus, sulfur and other substances. In the open air, it instantly interacts with oxygen and carbon dioxide, and therefore becomes covered with a gray coating.

Reacts violently with acids and sometimes ignites. In salts, calcium exhibits interesting properties. For example, cave stalactites and stalagmites are calcium carbonate, gradually formed from water, carbon dioxide and bicarbonate as a result of processes within groundwater.

Due to its high activity in its normal state, calcium is stored in laboratories in dark, sealed glass containers under a layer of paraffin or kerosene. A qualitative reaction to calcium ion is the coloring of the flame in a rich brick-red color.

Calcium turns flames red

Calcium turns flames red

The metal in the composition of compounds can be identified by insoluble precipitates of some salts of the element (fluoride, carbonate, sulfate, silicate, phosphate, sulfite).

Reaction of water with calcium

Calcium is stored in jars under a layer of protective liquid. To conduct a demonstration of how the reaction of water and calcium occurs, you cannot simply take out the metal and cut off the desired piece from it. It is easier to use calcium metal in the laboratory in the form of shavings.

If there are no metal shavings and there are only large chunks of calcium in the jar, you will need pliers or a hammer. The finished piece of calcium of the required size is placed in a flask or glass of water. Calcium shavings are placed in a bowl in a gauze bag.

Calcium sinks to the bottom, and the release of hydrogen begins (first at the place where the fresh fracture of the metal is located). Gradually, gas is released from the surface of the calcium. The process resembles violent boiling, and at the same time a precipitate of calcium hydroxide (slaked lime) is formed.

Lime slaking

Lime slaking

A piece of calcium floats up, caught up in hydrogen bubbles. After about 30 seconds, the calcium dissolves and the water turns cloudy white due to the formation of a hydroxide suspension. If the reaction is carried out not in a beaker, but in a test tube, you can observe the release of heat: the test tube quickly becomes hot. The reaction of calcium with water does not end with a spectacular explosion, but the interaction of the two substances proceeds vigorously and looks spectacular. The experience is safe.

If the bag with the remaining calcium is removed from the water and held in air, then after some time, as a result of the ongoing reaction, strong heating will occur and the remaining calcium in the gauze will boil. If part of the cloudy solution is filtered through a funnel into a glass, then when carbon monoxide CO₂ is passed through the solution, a precipitate will form. This does not require carbon dioxide - you can blow exhaled air into the solution through a glass tube.

Home / Lectures 1st year / General and organic chemistry / Question 23. Calcium / 2. Physical and chemical properties

Physical properties. Calcium is a silver-white malleable metal that melts at a temperature of 850 degrees. C and boils at 1482 degrees. C. It is significantly harder than alkali metals.

Chemical properties. Calcium is an active metal. So, under normal conditions, it easily interacts with atmospheric oxygen and halogens:

2 Ca + O2 = 2 CaO (calcium oxide);

Ca + Br2 = CaBr2 (calcium bromide).

Calcium reacts with hydrogen, nitrogen, sulfur, phosphorus, carbon and other non-metals when heated:

Ca + H2 = CaH2 (calcium hydride);

3 Ca + N2 = Ca3N2 (calcium nitride);

Ca + S = CaS (calcium sulfide);

3 Ca + 2 P = Ca3P2 (calcium phosphide);

Ca + 2 C = CaC2 (calcium carbide).

Calcium reacts slowly with cold water, but very vigorously with hot water:

Ca + 2 H2O = Ca(OH)2 + H2.

Calcium can remove oxygen or halogens from oxides and halides of less active metals, i.e. it has reducing properties:

5 Ca + Nb2O5 = CaO + 2 Nb;

- 1. Being in nature

- 3. Receipt

- 4. Application

www.medkurs.ru

Calcium | directory Pesticides.ru

For many people, knowledge about calcium is limited only to the fact that this element is necessary for healthy bones and teeth. Where else it is contained, why it is needed and how necessary it is, not everyone has an idea. However, calcium is found in many familiar compounds, both natural and man-made. Chalk and lime, stalactites and stalagmites of caves, ancient fossils and cement, gypsum and alabaster, dairy products and anti-osteoporosis drugs - all this and much more is high in calcium.

This element was first obtained by G. Davy in 1808, and at first it was not particularly actively used. However, this metal is now the fifth most produced in the world, and the need for it is increasing year by year. The main area of use of calcium is the production of building materials and mixtures. However, it is necessary to build not only houses, but also living cells. In the human body, calcium is part of the skeleton, makes muscle contractions possible, ensures blood clotting, regulates the activity of a number of digestive enzymes and performs other quite numerous functions. It is no less important for other living objects: animals, plants, fungi and even bacteria. At the same time, the need for calcium is quite high, which makes it possible to classify it as a macronutrient.

Calcium, Ca is a chemical element of the main subgroup of group II of the Mendeleev periodic system. Atomic number – 20. Atomic mass – 40.08.

Calcium is an alkaline earth metal. When free, malleable, fairly hard, white. By density it belongs to light metals.

- Density – 1.54 g/cm3,

- Melting point – +842 °C,

- Boiling point – +1495 °C.

Calcium has pronounced metallic properties. In all compounds the oxidation state is +2.

In air it becomes covered with a layer of oxide, and when heated it burns with a reddish, bright flame. It reacts slowly with cold water, but quickly displaces hydrogen from hot water and forms hydroxide. When interacting with hydrogen, it forms hydrides. At room temperature it reacts with nitrogen, forming nitrides. It also easily combines with halogens and sulfur, and reduces metal oxides when heated.

Calcium is one of the most abundant elements in nature. In the earth's crust its content is 3% of the mass. It occurs in the form of deposits of chalk, limestone, and marble (a natural type of calcium carbonate CaCO3). There are large quantities of deposits of gypsum (CaSO4 x 2h3O), phosphorite (Ca3(PO4)2 and various calcium-containing silicates.

Water

. Calcium salts are almost always present in natural water. Of these, only gypsum is slightly soluble in it. When water contains carbon dioxide, calcium carbonate goes into solution in the form of bicarbonate Ca(HCO3)2.Hard water

. Natural water with a large amount of calcium or magnesium salts is called hard water.Soft water

. When the content of these salts is low or absent, the water is called soft.Soils

. As a rule, soils are sufficiently provided with calcium. And, since calcium is contained in greater mass in the vegetative part of plants, its removal with the harvest is insignificant.Loss of calcium from the soil occurs as a result of its leaching by precipitation. This process depends on the granulometric composition of the soil, the amount of precipitation, the type of plants, the forms and doses of lime and mineral fertilizers. Depending on these factors, calcium losses from the arable layer range from several tens to 200 – 400 kg/ha or more.

Calcium content in different types of soils

Podzolic soils contain 0.73% (of soil dry matter) calcium.

Gray forest – 0.90% calcium.

Chernozems – 1.44% calcium.

Serozems – 6.04% calcium.

In the plant, calcium is found in the form of phosphates, sulfates, carbonates, and in the form of salts of pectic and oxalic acids. Almost up to 65% of calcium in plants can be extracted with water. The rest is treated with weak acetic and hydrochloric acids. Most calcium is found in aging cells.

Symptoms of calcium deficiency according to: |

|

Culture | Symptoms of deficiency |

General symptoms | Whitening of the apical bud; Whitening of young leaves; The tips of the leaves are curved down; The edges of the leaves curl upward; |

Potato | The upper leaves bloom poorly; The growing point of the stem dies; There is a light stripe at the edges of the leaves, which later darkens; The edges of the leaves are curled upward; |

White and cauliflower cabbage | The leaves of young plants have chlorotic spotting (marbling) or white stripes along the edges; In old plants, leaves curl and burns appear on them; The growing point dies off |

The terminal lobes of leaves die off Flowers fall; A dark spot appears on the fruit in the apical part, which increases as the fruit grows (tomato blossom end rot) |

|

The apical buds die off; The edges of young leaves are curled up, have a ragged appearance, and subsequently die off; The upper parts of the shoots die off; Damage to root tips; There are brown spots in the fruit pulp (bitter pitting); The taste of the fruit deteriorates; Marketability of fruits decreases |

Functions of calcium

The effect of this element on plants is multifaceted and, as a rule, positive. Calcium:

- Strengthens metabolism;

- Plays an important role in the movement of carbohydrates;

- Affects the metamorphosis of nitrogenous substances;

- Accelerates the consumption of reserve proteins of seeds during germination;

- Plays a role in the process of photosynthesis;

- a strong antagonist of other cations, preventing their excess entry into plant tissues;

- Affects the physicochemical properties of protoplasm (viscosity, permeability, etc.), and therefore the normal course of biochemical processes in the plant;

- Calcium compounds with pectin substances glue the walls of individual cells together;

- Affects enzyme activity.

It should be noted that the influence of calcium compounds (lime) on enzyme activity is expressed not only in direct action, but also due to the improvement of the physico-chemical properties of the soil and its nutritional regime. In addition, liming the soil significantly affects the processes of vitamin biosynthesis.

Lack (deficiency) of calcium in plants

Lack of calcium primarily affects the development of the root system. The formation of root hairs on the roots stops. The outer root cells are destroyed.

This symptom manifests itself both with a lack of calcium and with an imbalance in the nutrient solution, that is, the predominance of monovalent cations of sodium, potassium and hydrogen in it.

In addition, the presence of nitrate nitrogen in the soil solution increases the supply of calcium to plant tissues, and reduces the supply of ammonia.

Signs of calcium starvation are expected when the calcium content is less than 20% of the cation exchange capacity of the soil.

Symptoms Visually, calcium deficiency is determined by the following signs:

- The roots of plants have damaged tips with a brown color;

- The growing point becomes deformed and dies;

- Flowers, ovaries and buds fall off;

- The fruits are damaged by necrosis;

- The leaves are noted to be chlorotic;

- The apical bud dies and stem growth stops.

Cabbage, alfalfa, and clover are highly sensitive to the presence of calcium. It has been established that these same plants are also characterized by increased sensitivity to soil acidity.

Mineral calcium poisoning results in interveinal chlorosis with whitish necrotic spots. They may be colored or have concentric rings filled with water. Some plants respond to excess calcium by growing leaf rosettes, dying shoots and dropping leaves. The symptoms are similar in appearance to iron and magnesium deficiency.

The source of calcium replenishment in the soil is lime fertilizers. They are divided into three groups:

- Hard calcareous rocks;

- Soft calcareous rocks;

- Industrial waste with high lime content.

Based on the content of CaO and MgO, hard calcareous rocks are divided into:

- limestones (55–56% CaO and up to 0.9% MgO);

- dolomitized limestones (42–55% CaO and up to 9% MgO);

- dolomites (32–30% CaO and 18–20% MgO).

Limestones

– basic lime fertilizers. Contains 75–100% Ca and Mg oxides calculated as CaCO3.Dolomitized limestone

. Contains 79–100% active substance (a.i.) calculated as CaCO3. Recommended in crop rotations with potatoes, legumes, flax, root crops, as well as on highly podzolized soils.Marl

. Contains up to 25–15% CaCO3 and impurities in the form of clay and sand up to 20–40%. Acts slowly. Recommended for use on light soils.Chalk

. Contains 90–100% CaCO3. The action is faster than that of limestone. It is a valuable lime fertilizer in finely ground form.Burnt lime

(CaO). The CaCO3 content is over 70%. It is characterized as a strong and fast acting liming material.Slaked lime

(Ca(OH)2). CaCO3 content – 35% or more. It is also a strong and fast acting lime fertilizer.Dolomite flour

. The content of CaCO3 and MgCO3 is about 100%. Its action is slower than that of calcareous tuffs. Typically used where magnesium is required.Calcareous tuffs

. Content of CaCO3 – 15–96%, impurities – up to 25% clay and sand, 0.1% P2O5. The action is faster than that of limestone.Defecation dirt (defecation)

. Consists of CaCO3 and Ca(OH)2. The lime content of CaO is up to 40%. Nitrogen is also present - 0.5% and P2O5 - 1-2%. This is waste from beet sugar factories. It is recommended for use not only to reduce soil acidity, but also in beet growing areas on chernozem soils.Shale ash cyclones

. Dry dusty material. The content of the active substance is 60–70%. Refers to industrial waste.Dust from furnaces and cement factories

. The CaCO3 content must exceed 60%. In practice, it is used in farms located in close proximity to cement plants.Metallurgical slags

. Used in the regions of the Urals and Siberia. Non-hygroscopic, easy to spray. Must contain at least 80% CaCO3 and have a moisture content of no more than 2%. The granulometric composition is important: 70% - less than 0.25 mm, 90% - less than 0.5 mm.Organic fertilizers. The Ca content in terms of CaCO3 is 0.32–0.40%.

Phosphorite flour. Calcium content – 22% CaCO3.

Lime fertilizers are used not only to provide soil and plants with calcium. The main purpose of their use is soil liming. This is a method of chemical reclamation. It is aimed at neutralizing excess soil acidity, improving its agrophysical, agrochemical and biological properties, supplying plants with magnesium and calcium, mobilizing and immobilizing macroelements and microelements, creating optimal water-physical, physical, air conditions for the life of cultivated plants.

Efficiency of soil liming

Simultaneously with satisfying the needs of plants for calcium as an element of mineral nutrition, liming leads to multiple positive changes in soils.

The effect of liming on the properties of some soils

Calcium promotes the coagulation of soil colloids and prevents their leaching. This leads to easier tillage and improved aeration.

As a result of liming:

- sandy humus soils increase their water absorption capacity;

- On heavy clay soils, soil aggregates and clumping are formed, which improve water permeability.

In particular, organic acids are neutralized and H-ions are displaced from the absorbing complex. This leads to the elimination of metabolic acidity and a decrease in hydrolytic acidity of the soil. At the same time, an improvement in the cationic composition of the soil absorption complex is observed, which occurs due to the replacement of hydrogen and aluminum ions with calcium and magnesium cations. This increases the degree of soil saturation with bases and increases the absorption capacity.

The effect of liming on the supply of nitrogen to plants

After liming, the positive agrochemical properties of the soil and its structure can be maintained for several years. This helps create favorable conditions for enhancing beneficial microbiological processes for the mobilization of nutrients. The activity of ammonifiers, nitrifiers, and nitrogen-fixing bacteria that live freely in the soil increases.

Liming helps to increase the proliferation of nodule bacteria and improve the supply of nitrogen to the host plant. It has been established that bacterial fertilizers lose their effectiveness on acidic soils.

The effect of liming on the supply of ash elements to plants

Liming helps supply the plant with ash elements, since it increases the activity of bacteria that decompose organic phosphorus compounds in the soil and promote the transition of iron and aluminum phosphates into calcium phosphate salts available to plants. Liming of acidic soils enhances microbiological and biochemical processes, which, in turn, increases the amount of nitrates, as well as digestible forms of phosphorus and potassium.

Effect of liming on the forms and availability of macroelements and microelements

Liming increases the amount of calcium, and when using dolomite flour - magnesium. At the same time, toxic forms of manganese and aluminum become insoluble and pass into the precipitated form. The availability of elements such as iron, copper, zinc, manganese is decreasing. Nitrogen, sulfur, potassium, calcium, magnesium, phosphorus and molybdenum become more available.

The influence of liming on the action of physiologically acidic fertilizers

Liming increases the effectiveness of physiologically acidic mineral fertilizers, especially ammonia and potash.

The positive effect of physiologically acidic fertilizers without the addition of lime fades, and over time can turn negative. So, in fertilized areas, yields are even less than in unfertilized areas. The combination of liming with the use of fertilizers increases their effectiveness by 25–50%.

When liming, enzymatic processes in the soil are activated, by which its fertility is indirectly judged.

Compiled by: Grigorovskaya P.I.

Page added: 05.12.13 00:40

Last update: 05/22/14 16:25

Literary sources:

Glinka N.L. General chemistry. Textbook for universities. Publisher: Leningrad: Chemistry, 1985, p. 731

Mineev V.G. Agrochemistry: Textbook. – 2nd edition, revised and expanded. – M.: Moscow State University Publishing House, KolosS Publishing House, 2004. – 720 p., l. ill.: ill. – (Classical university textbook).

Petrov B.A., Seliverstov N.F. Mineral nutrition of plants. A reference guide for students and gardeners. Ekaterinburg, 1998. 79 p.

Encyclopedia for children. Volume 17. Chemistry. / Head. ed. V.A. Volodin. – M.: Avanta +, 2000. – 640 p., ill.

Yagodin B.A., Zhukov Yu.P., Kobzarenko V.I. Agrochemistry / Edited by B.A. Yagodina. – M.: Kolos, 2002. – 584 pp.: ill (Textbooks and teaching aids for students of higher educational institutions).

Images (reworked):

20 Ca Calcium, licensed under CC BY

Calcium deficiency in wheat, by CIMMYT, licensed under CC BY-NC-SA

www.pesticidy.ru

Calcium and its role for humanity - Chemistry

Calcium and its role for humanity

Introduction

Being in nature

Receipt

Physical properties

Chemical properties

Application of calcium compounds

Biological role

Conclusion

Bibliography

Introduction

Calcium is an element of the main subgroup of the second group, the fourth period of the periodic system of chemical elements of D.I. Mendeleev, with atomic number 20. It is designated by the symbol Ca (lat. Calcium). The simple substance calcium (CAS number: 7440-70-2) is a soft, reactive alkaline earth metal of a silvery-white color.

Despite the ubiquity of element No. 20, even chemists have not all seen elemental calcium. But this metal, both in appearance and in behavior, is completely different from alkali metals, contact with which is fraught with the danger of fires and burns. It can be safely stored in air; it does not ignite from water. The mechanical properties of elemental calcium do not make it a “black sheep” in the family of metals: calcium surpasses many of them in strength and hardness; it can be turned on a lathe, drawn into wire, forged, pressed.

And yet, elemental calcium is almost never used as a structural material. He's too active for that. Calcium easily reacts with oxygen, sulfur, and halogens. Even with nitrogen and hydrogen, under certain conditions, it reacts. The environment of carbon oxides, inert for most metals, is aggressive for calcium. It burns in an atmosphere of CO and CO2.

History and origin of the name

The name of the element comes from Lat. calx (in the genitive case calcis) -- “lime”, “soft stone”. It was proposed by the English chemist Humphry Davy, who isolated calcium metal by the electrolytic method in 1808. Davy electrolyzed a mixture of wet slaked lime and mercuric oxide HgO on a platinum plate, which served as the anode. The cathode was a platinum wire immersed in liquid mercury. As a result of electrolysis, calcium amalgam was obtained. Having distilled mercury from it, Davy obtained a metal called calcium.

Calcium compounds - limestone, marble, gypsum (as well as lime - a product of limestone firing) have been used in construction for several thousand years ago. Until the end of the 18th century, chemists considered lime to be a simple solid. In 1789, A. Lavoisier suggested that lime, magnesia, barite, alumina and silica are complex substances.

Being in nature

Due to its high chemical activity, calcium does not occur in free form in nature.

Calcium accounts for 3.38% of the mass of the earth's crust (5th most abundant after oxygen, silicon, aluminum and iron).

Isotopes. Calcium occurs in nature as a mixture of six isotopes: 40Ca, 42Ca, 43Ca, 44Ca, 46Ca and 48Ca, among which the most common - 40Ca - is 96.97%.

Of the six natural isotopes of calcium, five are stable. The sixth isotope, 48Ca, the heaviest of the six and very rare (its isotopic abundance is only 0.187%), was recently discovered to undergo double beta decay with a half-life of 5.3 x 1019 years.

In rocks and minerals. Most of the calcium is contained in silicates and aluminosilicates of various rocks (granites, gneisses, etc.), especially in feldspar - Ca anorthite.

In the form of sedimentary rocks, calcium compounds are represented by chalk and limestones, consisting mainly of the mineral calcite (CaCO3). The crystalline form of calcite - marble - is much less common in nature.

Calcium minerals such as calcite CaCO3, anhydrite CaSO4, alabaster CaSO4 0.5h3O and gypsum CaSO4 2h3O, fluorite CaF2, apatite Ca5(PO4)3(F,Cl,OH), dolomite MgCO3 CaCO3 are quite widespread. The presence of calcium and magnesium salts in natural water determines its hardness.

Calcium, vigorously migrating in the earth's crust and accumulating in various geochemical systems, forms 385 minerals (the fourth largest number of minerals).

Migration in the earth's crust. In the natural migration of calcium, a significant role is played by “carbonate equilibrium”, associated with the reversible reaction of the interaction of calcium carbonate with water and carbon dioxide with the formation of soluble bicarbonate:

CaCO3 + h3O + CO2 - Ca (HCO3)2 - Ca2+ + 2HCO3-

(equilibrium shifts to the left or right depending on the concentration of carbon dioxide).

Biogenic migration. In the biosphere, calcium compounds are found in almost all animal and plant tissues (see also below). A significant amount of calcium is found in living organisms. Thus, hydroxyapatite Ca5(PO4)3OH, or, in another entry, 3Ca3(PO4)2·Ca(OH)2, is the basis of the bone tissue of vertebrates, including humans; The shells and shells of many invertebrates, eggshells, etc. are made of calcium carbonate CaCO3. In living tissues of humans and animals there is 1.4-2% Ca (by mass fraction); in a human body weighing 70 kg, the calcium content is about 1.7 kg (mainly in the intercellular substance of bone tissue).

Receipt

Free metallic calcium is obtained by electrolysis of a melt consisting of CaCl2 (75-80%) and KCl or from CaCl2 and CaF2, as well as aluminothermic reduction of CaO at 1170-1200 °C:

4CaO + 2Al = CaAl2O4 + 3Ca.

Physical properties

Calcium metal exists in two allotropic modifications. Up to 443 °C, ?-Ca with a cubic face-centered lattice (parameter a = 0.558 nm) is stable; higher stable is ?-Ca with a cubic body-centered lattice of the ?-Fe type (parameter a = 0.448 nm). Standard enthalpy?H0 transition? > ? is 0.93 kJ/mol.

Chemical properties

Calcium is a typical alkaline earth metal. The chemical activity of calcium is high, but lower than that of all other alkaline earth metals. It easily reacts with oxygen, carbon dioxide and moisture in the air, which is why the surface of calcium metal is usually dull gray, so in the laboratory calcium is usually stored, like other alkaline earth metals, in a tightly closed jar under a layer of kerosene or liquid paraffin.

In the series of standard potentials, calcium is located to the left of hydrogen. The standard electrode potential of the Ca2+/Ca0 pair is ? 2.84 V, so that calcium actively reacts with water, but without ignition:

Ca + 2H2O = Ca(OH)2 + H2^ + Q.

Calcium reacts with active non-metals (oxygen, chlorine, bromine) under normal conditions:

2Ca + O2 = 2CaO, Ca + Br2 = CaBr2.

When heated in air or oxygen, calcium ignites. Calcium reacts with less active non-metals (hydrogen, boron, carbon, silicon, nitrogen, phosphorus and others) when heated, for example:

Ca + H2 = CaH2, Ca + 6B = CaB6,

3Ca + N2 = Ca3N2, Ca + 2C = CaC2,

3Ca + 2P = Ca3P2 (

calcium phosphide), calcium phosphides of the compositions CaP and CaP5 are also known;

2Ca + Si = Ca2Si

(calcium silicide), calcium silicides of the compositions CaSi, Ca3Si4 and CaSi2 are also known.

The occurrence of the above reactions, as a rule, is accompanied by the release of a large amount of heat (that is, these reactions are exothermic). In all compounds with non-metals, the oxidation state of calcium is +2. Most of the calcium compounds with non-metals are easily decomposed by water, for example:

CaH2 + 2H2O = Ca(OH)2 + 2H2^,

Ca3N2 + 3H2O = 3Ca(OH)2 + 2Nh4^.

The Ca2+ ion is colorless. When soluble calcium salts are added to the flame, the flame turns brick-red.

Calcium salts such as CaCl2 chloride, CaBr2 bromide, CaI2 iodide and Ca(NO3)2 nitrate are highly soluble in water. Insoluble in water are fluoride CaF2, carbonate CaCO3, sulfate CaSO4, orthophosphate Ca3(PO4)2, oxalate CaC2O4 and some others.

It is important that, unlike calcium carbonate CaCO3, acidic calcium carbonate (bicarbonate) Ca(HCO3)2 is soluble in water. In nature, this leads to the following processes. When cold rain or river water, saturated with carbon dioxide, penetrates underground and falls on limestone, their dissolution is observed:

CaCO3 + CO2 + H2O = Ca(HCO3)2.

In the same places where water saturated with calcium bicarbonate comes to the surface of the earth and is heated by the sun's rays, a reverse reaction occurs:

Ca(HCO3)2 = CaCO3 + CO2^ + H2O.

This is how large masses of substances are transferred in nature. As a result, huge gaps can form underground, and beautiful stone “icicles” - stalactites and stalagmites - form in caves.

The presence of dissolved calcium bicarbonate in water largely determines the temporary hardness of water. It is called temporary because when water boils, bicarbonate decomposes and CaCO3 precipitates. This phenomenon leads, for example, to the fact that scale forms in the kettle over time.

Applications of calcium metal

The main use of calcium metal is as a reducing agent in the production of metals, especially nickel, copper and stainless steel. Calcium and its hydride are also used to produce difficult-to-reduce metals such as chromium, thorium and uranium. Calcium-lead alloys are used in batteries and bearing alloys. Calcium granules are also used to remove traces of air from vacuum devices.

Metallothermy

Pure metallic calcium is widely used in metallothermy for the production of rare metals.

Alloying of alloys

Pure calcium is used to alloy lead used for the production of battery plates and maintenance-free starter lead-acid batteries with low self-discharge. Also, metallic calcium is used for the production of high-quality calcium babbits BKA.

Nuclear fusion

The 48Ca isotope is the most effective and commonly used material for the production of superheavy elements and the discovery of new elements on the periodic table. For example, in the case of using 48Ca ions to produce superheavy elements in accelerators, the nuclei of these elements are formed hundreds and thousands of times more efficiently than when using other “projectiles” (ions).

Application of calcium compounds

Calcium hydride. By heating calcium in a hydrogen atmosphere, Cah3 (calcium hydride) is obtained, which is used in metallurgy (metallothermy) and in the production of hydrogen in the field.

Optical and laser materials. Calcium fluoride (fluorite) is used in the form of single crystals in optics (astronomical objectives, lenses, prisms) and as a laser material. Calcium tungstate (scheelite) in the form of single crystals is used in laser technology and also as a scintillator.

Calcium carbide. Calcium carbide CaC2 is widely used for the production of acetylene and for the reduction of metals, as well as in the production of calcium cyanamide (by heating calcium carbide in nitrogen at 1200 °C, the reaction is exothermic, carried out in cyanamide furnaces).

Chemical current sources. Calcium, as well as its alloys with aluminum and magnesium, are used in backup thermal electric batteries as an anode (for example, calcium-chromate element). Calcium chromate is used in such batteries as a cathode. The peculiarity of such batteries is an extremely long shelf life (decades) in a suitable condition, the ability to operate in any conditions (space, high pressures), high specific energy in terms of weight and volume. Disadvantage: short lifespan. Such batteries are used where it is necessary to create colossal electrical power for a short period of time (ballistic missiles, some spacecraft, etc.).

Fireproof materials. Calcium oxide, both in free form and as part of ceramic mixtures, is used in the production of refractory materials.

Medicines. Calcium compounds are widely used as an antihistamine.

Calcium chloride

Calcium gluconate

Calcium glycerophosphate

In addition, calcium compounds are included in drugs for the prevention of osteoporosis, in vitamin complexes for pregnant women and the elderly.

Biological role

Calcium is a common macronutrient in the body of plants, animals and humans. In humans and other vertebrates, most of it is contained in the skeleton and teeth in the form of phosphates. The skeletons of most groups of invertebrates (sponges, coral polyps, mollusks, etc.) consist of various forms of calcium carbonate (lime). Calcium ions are involved in blood clotting processes, as well as in ensuring constant osmotic pressure of the blood. Calcium ions also serve as one of the universal second messengers and regulate a variety of intracellular processes - muscle contraction, exocytosis, including the secretion of hormones and neurotransmitters, etc. The calcium concentration in the cytoplasm of human cells is about 10?7 mol, in intercellular fluids about 10 ?3 mol.

Calcium requirements depend on age. For adults, the required daily intake is from 800 to 1000 milligrams (mg), and for children from 600 to 900 mg, which is very important for children due to the intensive growth of the skeleton. Most of the calcium that enters the human body with food is found in dairy products; the remaining calcium comes from meat, fish, and some plant products (especially legumes). Absorption occurs in both the large and small intestines and is facilitated by an acidic environment, vitamin D and vitamin C, lactose, and unsaturated fatty acids. The role of magnesium in calcium metabolism is important; with its deficiency, calcium is “washed out” from the bones and deposited in the kidneys (kidney stones) and muscles.

Aspirin, oxalic acid, and estrogen derivatives interfere with the absorption of calcium. When combined with oxalic acid, calcium produces water-insoluble compounds that are components of kidney stones.

Due to the large number of processes associated with it, the calcium content in the blood is precisely regulated, and with proper nutrition, a deficiency does not occur. Prolonged absence from the diet can cause cramps, joint pain, drowsiness, growth defects, and constipation. Deeper deficiency leads to constant muscle cramps and osteoporosis. Abuse of coffee and alcohol can cause calcium deficiency, since some of it is excreted in the urine.

Excessive doses of calcium and vitamin D can cause hypercalcemia, followed by intense calcification of bones and tissues (mainly affecting the urinary system). Long-term excess disrupts the functioning of muscle and nerve tissues, increases blood clotting and reduces the absorption of zinc by bone cells. The maximum daily safe dose for an adult is 1500 to 1800 milligrams.

Products Calcium, mg/100 g

Sesame 783

Nettle 713

Forest mallow 505

Large plantain 412

Galinsoga 372

Sardines in oil 330

Ivy budra 289

Dog rose 257

Almond 252

Plantain lanceolist. 248

Hazelnut 226

Amaranth seed 214

Watercress 214

Soybeans dry 201

Children under 3 years old - 600 mg.

Children from 4 to 10 years old - 800 mg.

Children from 10 to 13 years old - 1000 mg.

Adolescents from 13 to 16 years old - 1200 mg.

Youth 16 and older - 1000 mg.

Adults from 25 to 50 years old - from 800 to 1200 mg.

Pregnant and breastfeeding women - from 1500 to 2000 mg.

Conclusion

Calcium is one of the most abundant elements on Earth. There is a lot of it in nature: mountain ranges and clay rocks are formed from calcium salts, it is found in sea and river water, and is part of plant and animal organisms.

Calcium constantly surrounds city dwellers: almost all main building materials - concrete, glass, brick, cement, lime - contain this element in significant quantities.

Naturally, having such chemical properties, calcium cannot exist in nature in a free state. But calcium compounds - both natural and artificial - have acquired paramount importance.

Bibliography

1. Editorial Board: Knunyants I. L. (chief editor) Chemical Encyclopedia: in 5 volumes - Moscow: Soviet Encyclopedia, 1990. - T. 2. - P. 293. - 671 p.

2. Doronin. N.A. Calcium, Goskhimizdat, 1962. 191 pp. with illustrations.

3. Dotsenko VA. - Therapeutic and preventive nutrition. - Question. nutrition, 2001 - N1-p.21-25

4. Bilezikian J. P. Calcium and bone metabolism // In: K. L. Becker, ed.

www.e-ng.ru

World of Science

Calcium is a metal element of the main subgroup II of group 4 of the periodic table of chemical elements. It belongs to the alkaline earth metal family. The outer energy level of the calcium atom contains 2 paired s-electrons

Which he is able to energetically give away during chemical interactions. Thus, Calcium is a reducing agent and in its compounds has an oxidation state of +2. In nature, calcium is found only in the form of salts. The mass fraction of calcium in the earth's crust is 3.6%. The main natural calcium mineral is calcite CaCO3 and its varieties - limestone, chalk, marble. There are also living organisms (for example, corals), the backbone of which consists mainly of calcium carbonate. Also important calcium minerals are dolomite CaCO3 MgCO3, fluorite CaF2, gypsum CaSO4 2h3O, apatite, feldspar, etc. Calcium plays an important role in the life of living organisms. The mass fraction of calcium in the human body is 1.4-2%. It is part of teeth, bones, other tissues and organs, participates in the process of blood clotting, and stimulates cardiac activity. To provide the body with a sufficient amount of calcium, you should definitely consume milk and dairy products, green vegetables, and fish. The simple substance calcium is a typical silver-white metal. It is quite hard, plastic, has a density of 1.54 g/cm3 and a melting point of 842? C. Chemically, calcium is very active. Under normal conditions, it easily interacts with oxygen and moisture in the air, so it is stored in hermetically sealed containers. When heated in air, calcium ignites and forms an oxide: 2Ca + O2 = 2CaO. Calcium reacts with chlorine and bromine when heated, and with fluorine even in the cold. The products of these reactions are the corresponding halides, for example: Ca + Cl2 = CaCl2. When calcium is heated with sulfur, calcium sulfide is formed: Ca + S = CaS. Calcium can also react with other non-metals. Interaction with water leads to the formation of slightly soluble calcium hydroxide and the release of hydrogen gas :Ca + 2h3O = Ca (OH) 2 + h3. Calcium metal is widely used. It is used as a rosette in the production of steels and alloys, and as a reducing agent for the production of some refractory metals.

Calcium is obtained by electrolysis of molten calcium chloride. Thus, calcium was first obtained in 1808 by Humphry Davy.

worldofscience.ru

Calcium is an element of the main subgroup of the second group, the fourth period of the periodic table of chemical elements, with atomic number 20. It is designated by the symbol Ca (lat. Calcium). The simple substance calcium (CAS number: 7440-70-2) is a soft, reactive alkaline earth metal of a silvery-white color.

History and origin of the name

The name of the element comes from Lat. calx (in the genitive case calcis) - “lime”, “soft stone”. It was proposed by the English chemist Humphry Davy, who isolated calcium metal by the electrolytic method in 1808. Davy electrolyzed a mixture of wet slaked lime and mercuric oxide HgO on a platinum plate, which served as the anode. The cathode was a platinum wire immersed in liquid mercury. As a result of electrolysis, calcium amalgam was obtained. Having distilled mercury from it, Davy obtained a metal called calcium.

Calcium compounds - limestone, marble, gypsum (as well as lime - a product of calcination of limestone) have been used in construction for several thousand years ago. Until the end of the 18th century, chemists considered lime to be a simple solid. In 1789, A. Lavoisier suggested that lime, magnesia, barite, alumina and silica are complex substances.

Receipt

Free metallic calcium is obtained by electrolysis of a melt consisting of CaCl 2 (75-80%) and KCl or CaCl 2 and CaF 2, as well as aluminothermic reduction of CaO at 1170-1200 °C:

4CaO + 2Al → CaAl 2 O 4 + 3Ca.

Physical properties

Calcium metal exists in two allotropic modifications. Up to 443 °C, α-Ca with a cubic face-centered lattice (parameter a = 0.558 nm) is stable; β-Ca with a cubic body-centered lattice of the α-Fe type (parameter a = 0.448 nm) is more stable. The standard enthalpy ΔH 0 of the α → β transition is 0.93 kJ/mol.

With a gradual increase in pressure, it begins to exhibit the properties of a semiconductor, but does not become a semiconductor in the full sense of the word (it is no longer a metal either). With a further increase in pressure, it returns to the metallic state and begins to exhibit superconducting properties (the temperature of superconductivity is six times higher than that of mercury, and far exceeds all other elements in conductivity). The unique behavior of calcium is similar in many ways to strontium (i.e., parallels in the periodic table remain).

Chemical properties

Calcium is a typical alkaline earth metal. The chemical activity of calcium is high, but lower than that of all other alkaline earth metals. It easily reacts with oxygen, carbon dioxide and moisture in the air, which is why the surface of calcium metal is usually dull gray, so in the laboratory calcium is usually stored, like other alkaline earth metals, in a tightly closed jar under a layer of kerosene or liquid paraffin.

See what “Legion (number)” is in other dictionaries